Shunxin Fertilizer Machinery is a leading compost production facility manufacturer in China. The fertilizer facility has been dedicated itself in compost machine manufacturing industry since 2005. With 15 years experiences in the organic compost fertilizer making machine manufacturing and marketing. The company has been well recognized by its customers at home and abroad.

In 2005, we relocated our factory in Xingyang industrial park. In our factory, there are more than 100 facilities for producing fertilizer equipment, including three laser cutting machines. What’s more, Shunxin has an expert team consisting of senior engineers who focus on refining and inventing more advanced fertilizer making machines. Customers need professional solutions for your fertilizer business, or waste recycling projects, can tell us, the company can provide you the best facilities meeting your requirements. Every year, the company has provided our customers project solutions form their farms, fertilizer factories, waste to fertilizer business, etc. almost thousands. Our compost facility, compost turners, compost pellet making machines, compost systems for the whole compost plants perform well in our customers’ plants. Meanwhile, these solutions have made profits for them. If you have tons of manure wastes, farm wastes, such as cow manure, poultry manure, they are all valuable raw materials to make composts, the company can provide you our best services with our compost production facilities, turning these organic into valuable compost fertilizers.

Economical compost facilities for your compost production

In Compost Turner Machine Making Factory, the compost fertilizer making machinery supplier manufactures quality fertilizer machines for our customers compost production plants. The company can not only provides our clients with best compost machines with reasonable prices, and also its applicable solutions for customers compost production plants’ reference. To turn your organic wastes, useful compost materials into compost fertilizers, the compost equipment making factory, provides customers different solutions, in different composting process.

-

Machines for Pre-composting: In the pre-composting process, when you make full preparations of the compost materials, the next thing, you need do is to turn the organic materials into a form more applicable for composting. Usually, there are solids, or too much water content in the organic wastes. To deal with this problem, the company produces cow dung dewatering machines, compost mixers, compost crushers, compost shredders, etc.

-

Machines Used in the Composting Process: When the pre-composting process done, move into the next step, compost making process. In the compost production process, the top work is how to make compost in a short time. In this composting production process, as a professional compost fertilizer production machine manufacturer, the company produces, compost tanks, fermenters, list of compost turners, such as windrow compost turners, groove type compost turners, crawler type compost turners, tractor type compost turners, for our clients compost production applications.

-

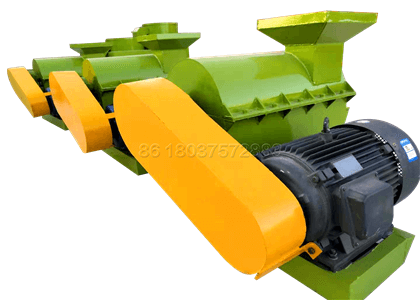

Equipment for Compost Deep Processing: Coming to the third compost making process, the compost fertilizer deep processing process, there are also many choices for our clients in our company. Some of you want to process the composts into pellets, there are different types of compost pellet making machines for your compost making requirements. What’s more, if customers want to make composts more in a large scale, or you want to produce compost fertilizer more efficiently, there are compost packing machines, bagging machines, belt conveyors, robot pelletizers, for your commercial compost making purpose.

-

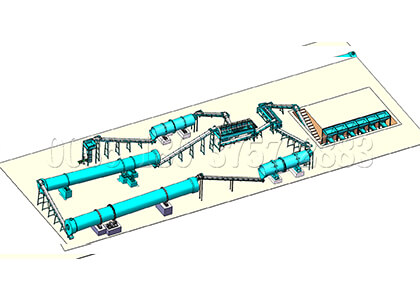

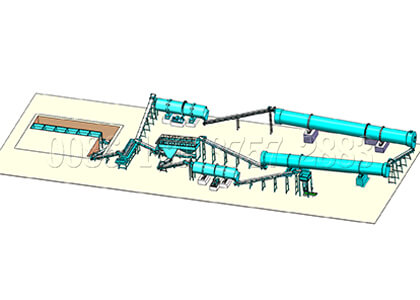

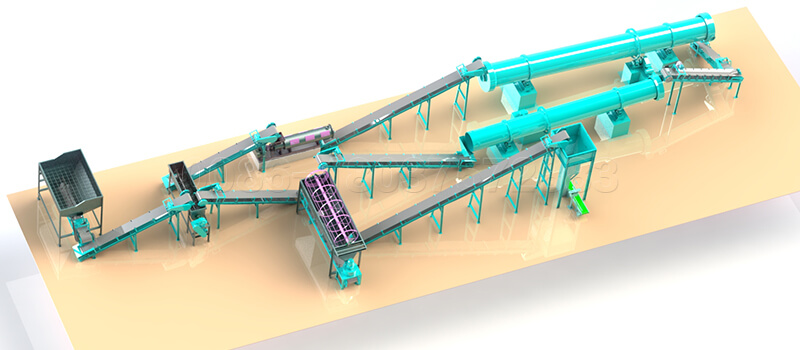

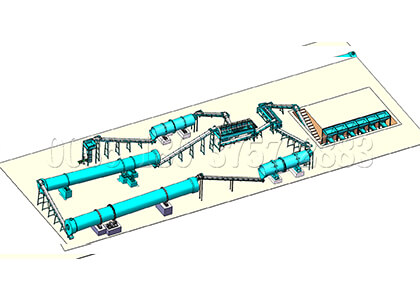

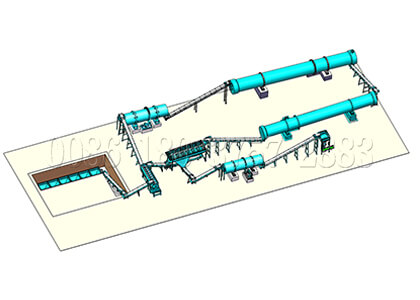

Turnkey Project Solutions for Compost A to Z: Apart from the above three composting process solutions you can choose from our company, there are also turnkey compost making solutions for your compost production business. There are organic waste fertilizer production lines, manure compost production lines, bio compost fertilizer lines solutions, all organic composts plant solutions you need, the company can tailor it for your compost making factory. First of all, we can provide you full ranges of compost production lines facilities. Secondly, we can provide you compost plant layout services, compost plant project design solutions, etc. Thirdly, there are also professional engineers help you install the compost facilities for you. The following listed compost facility, compost technology you can use, and recommended compost materials just for your compost production reference.

Cost-effective precompost machines for sale in Shunxin

Cow Dung Dewatering Machine

Compost Feeding Equipment

Compost Crusher

Compost Mulcher

Compost fertilizer making machine for sale

Compost Line

Indoor Composting Machine

Turner Tractor

Commercial Compost Machine

Waste to Fertilizer Machine

Organic Waste Composter

Bio composter machine

Compost Windrow Turner

Waste Composting Machine

Garbage Compost Making Machine

Manure Composting Equipment

Self-propelled Compost Turner

Mulch Turner

Compost Crusher

Compost Mixer

Electronic Batching Scale

Compost technology you shall know for quality composting

Composting Process

Reactor Composting

Groove Composting

Static Composting

What organic materials are perfect for your compost plants?

Poultry Manure Composting

Chemical Composting

Wood Waste Composting

Sludge Composting

Manure Waste Composting

Livestock Composting

5 Hot sale compost turner machines

Composting equipment can be generally divided into ground windrow composting equipment, groove type composting facility and vertical composting reactor according to local climate and floor space.

Spiral windrow compost turning machine

The device is mainly used for turning and supplying oxygen to the pile under the condition of windrow fermentation. Horizontal spiral turning structure, hydraulic lifting, crawler walking system. The rotating spiral roller gathers the triangular strip material in the middle, and at the same time, the material is turned backwards as the drum rotates, it is thoroughly mixed with the internal materials, the material and oxygen are in full contact, and the hot air in the stack is exposed. Thereby achieving material mixing, ventilation, aeration, and turning, to achieve the purpose of composting fermentation.

Crawler Windrow Compost Turning Specification

- Processing capacity: 400 to 800 cubic meters/h, stacking width 2.0~4.0m, Stacking height 1.0~2.0m;

- Supporting power: 22 to 45kW;

- Forward/reverse speed: 5 to 15m/min;

- The supporting civil construction investment is small, suitable for composting in dry areas.

- Track-type self-propelled equipment, convenient and reliable in operation and good adhesion;

- It has a two-speed working state, its drum is running at a low speed, and other times can be driven at a high speed;

- When the spiral drum is not working, the hydraulic system can lift the drum to increase the gap with the ground;

- The detachable spiral blade is adopted, which is convenient for maintenance and replacement, and has good interchangeability.

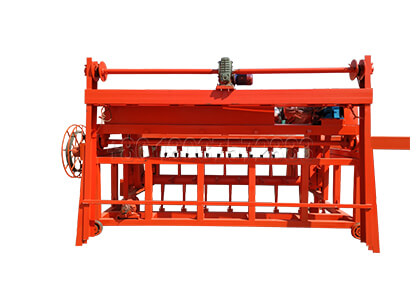

Chain plate type compost turning equipment for sale

The chain type compost turner equipment is mainly used for turning and supplying oxygen to the compost windrow pile under the condition of trough type fermentation. The chain plate conveys the dumping structure and hydraulic lifting. This high-efficiency turning operation turning machine helps to accelerate the fermentation of the material in the fermentation tank, reduce moisture and improve the stability of the material after fermentation.

Chain plate windrow compost facility equipment

- The width of the flip chain is 2.0m, and the throwing distance is 4m each time;

- The width of the fermentation tank is 2, 0 to 9.0 m, and the maximum height of the material layer is 1.8 m;

- The processing capacity: 65 cubic meters/d;

- Supporting power: 22 to 45kW;

- The forward speed is 90m/h, and the reverse speed is 360m/h;

- The optimized multi-tooth chain plate structure has low running resistance and is very suitable for deep groove operation;

- It can realize the operation at any position in the groove by lateral and longitudinal displacement;

- The horizontal movement distance of the material is large and the high position is thrown, and the contact with the air is sufficient, and the water is easy to drop;

- The hydraulic control system is used for lifting and lowering the raft, which is reliable and fast;

Technical highlights design

- The optimized multi-tooth chain plate structure has low running resistance and is very suitable for deep groove operation;

- It can realize the operation at any position in the groove by lateral and longitudinal displacement;

- The horizontal movement distance of the material is large and the high position is thrown, and the contact with the air is sufficient, and the water is easy to drop;

- The hydraulic control system is used for lifting and lowering the raft, which is reliable and fast;

- The slewing chain plate is sturdy and durable, the whole machine runs smoothly, and the material after the turning is even and even;

- Centralized control of the control cabinet, which can be manually controlled, automatically controlled or remotely controlled, equipped with a safety travel switch;

- The area is small, suitable for occasions with large volume, humid climate and continuous fermentation.

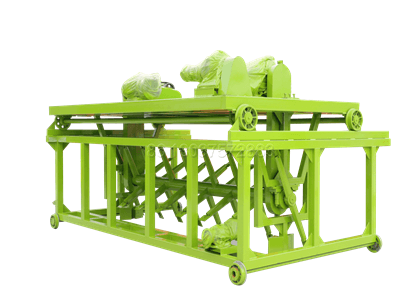

Paddle-type compost turning machine

This compost turner machine is also a groove type compost turner machine with paddle and gear, hydraulic lifting system structural design. Its traveling mechanism realizes the walking along the track of the fermenting tank by the traveling gear motor. The geared motor transmits the power to the turning main shaft through the chain, and the turning throwing spindle drives the paddle tooth to perform the full-width turning operation on the material pile to realize the full contact of the material with the air. When it is necessary to advance or retreat without turning, the hydraulic lifting mechanism can lift the paddle and the upper cover to lift.

- The width of the turning part is 6.0m, and the distance of each throwing is 1.2~2, 0m;

- The width of the fermentation tank is 6,0 m, and the height of the layer is 0.9 to 2 m;

- Supporting power 26,5~41.5kW;

- The forward speed is 50m/h, and the reverse speed is 100m/h;

- Hydraulic automatic control lifting mechanism, flexible work, safe and reliable;

- The working parts are wear-resistant, corrosion-resistant and removable, and have certain crushing and stirring functions for the materials;

- The combination of on-site centralized control and remote control makes operation more convenient;

- It can realize the turning operation in the forward and reverse directions, and the work efficiency is high;

- Continuous or whole tank fermentation can be realized

Wheel type compost turner machine technical advantages

- Hydraulic automatic control lifting mechanism, flexible work, safe and reliable;

- The working parts are wear-resistant, corrosion-resistant and removable, and have certain crushing and stirring functions for the materials;

- The combination of on-site centralized control and remote control makes operation more convenient;

- It can realize the turning operation in the forward and reverse directions, and the work efficiency is high;

- Continuous or whole tank fermentation can be realized;

Because the turning part is a removable wear-resistant paddle structure and the material layer is shallow, it is suitable for medium-production, humid climate, continuous or batch fermentation occasions, especially suitable for stones, irons and ropes.

Shunxin compost reactor tank for sale

It is a kind of aerobic composting device integrating waste collection, storage and fermenting and decomposing functions. The compost tank is suitable for the disposal of small and medium-sized farm manure and domestic garbage in residential quarters. The fermenting tank is in a vertical structure with multiple aeration system.

- Processing capacity: 2 to 10t/d.

- Total installed power: 30kW.

- Continuous fermentation, at any time than expected, set daily waste collection, storage and fertilizer treatment in one.

- The reactor is sealed, and the amount of odor to be treated is large.

- The aeration system is integrated in the agitator, and the oxygen is supplied accurately in the blade mixing place in time, and the aeration is sufficient and the efficiency is higher.

- The structure is compact, there is no need to build a factory building, and the fixed investment is small.

- Simple operation, regular mixing and aeration, one device is equivalent to one factory.

- Model: SXXZF-2500

- Weight: 2.5t

- Power: 30HP

- Capacity: 300-500 m3/h

- Dim.: 3300*2400*2000mm

- Working speed: 6-12 m/min

- Turning width: 2500 mm

- Turning height: 600-800 mm

- Row spacing: 600-800 mm

- Material max. particle dia.: 250 mm

- Diesel engine: Weichai

Compost turner yeoman tractor specifications

Model: SX-300 Color: Yellow(can be customized) Size: 4930*1620*2660mm Application: Turning organic wastes piles Feature: Also can be used as a forklift

Top universities our factory cooperates with

Some companies our factory has forged strong cooperational relationships

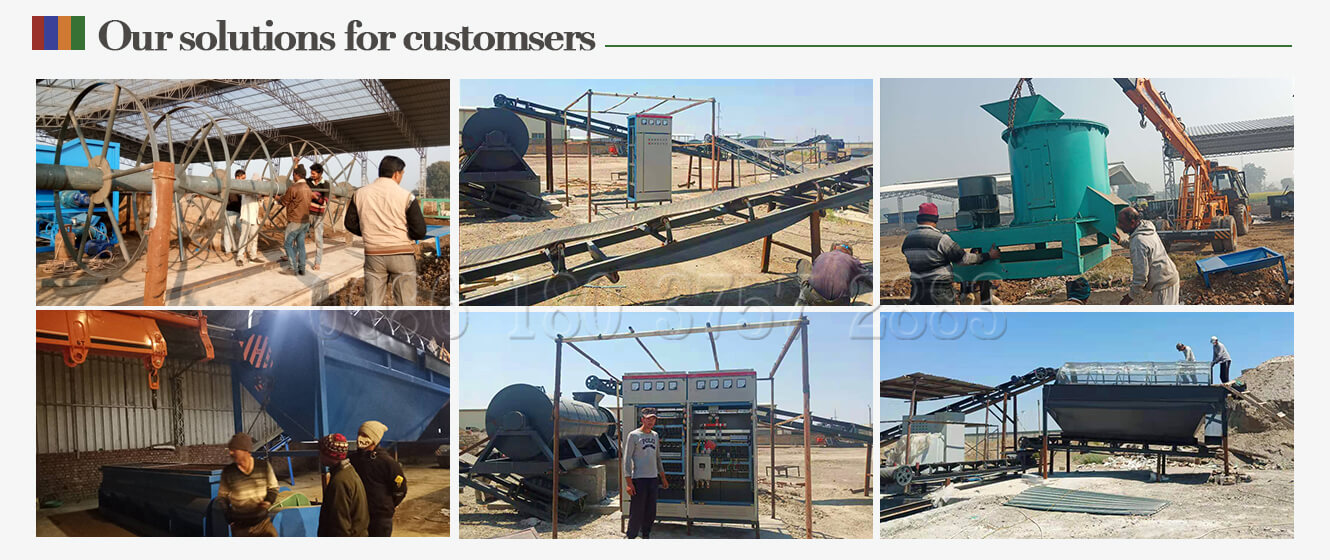

Project Solutions