Due to the high moisture content, high corrosivity, poor fluidity and strong adhesion of organic raw materials, equipment such as scraper conveyors and screw conveyors can hardly be used for fertilizer transportation. Fertilizer belt conveyors and chain bucket elevators can be used in raw materials and finished compost products delivery. The belt conveyor has the advantages of large conveying capacity, simple structure, convenient maintenance and standardization of components. It is widely used in mining, metallurgy, coal and other industries to transport loose materials or finished articles. According to the transportation process requirements, it can be transported in a single unit. It can also be used as a horizontal or inclined conveying system composed of or with other conveying equipment to meet the needs of different layout types of production lines. It is suitable for conveying powder density and granularity with a bulk density of less than 1.67/ton/cubic meters. Small pieces of low-friction materials and bagged materials, such as coal, gravel, sand, cement, fertilizer, grain, etc. The temperature of the material to be delivered is less than 60 °C. The captain and assembly form can be determined according to user requirements. The driving system of the conveyor can be used with an electric roller or with a drive frame.

Structural features of ShunXin compost belt conveyor

It is especially suitable for materials with high corrosivity and easy adhesion. The driving drum squirrel cage structure and the idler are in the form of a bidirectional spiral rubber roller.

Compost fertilizer conveying equipment working principle

The belt conveyor for organic manure transmitting is a machine that performs the conveying task by using the movement of the belt to make the material flow in the direction of the belt movement according to the friction transmission principle. It is used to bridge the fertilizer production equipment to achieve continuity and automation of the production process, improving production efficiency and reduce labor intensity of the fertilizer plants.

What is the working performance of ShunXin manufactured belt conveyors for fertilizer plants?

- Production capacity: 1.0 ~ 10.0 t / h;

- Supporting power: 1.5~10·0kW;

- Belt width: 0.3~1.5m;

- Large amount of transportation and low energy consumption;

- Low noise and easy maintenance;

- Large conveying volume, open structure, the organic material is easy to be exposed to the air;

- For the characteristics of organic materials, the driving drum should be in the form of a squirrel cage, and the roller should be in the form of a two-way spiral rubber roller to prevent material sticking and belt deviation;

- The inclined conveying angle of the belt conveyor is generally 0 to 25 degrees. In order to shorten the distance between the two devices, a large inclination angle ribbing belt can be used.

Easy ways to extend promote your fertilizer belt conveyors working performance

Regular inspection, and in time maintenance to different parts of the belt conveyor machine will extend the machines service life. And the machine’s working performance will be also promoted in the meantime. The following tips in the conveyors maintenance and inspection, just for your reference.

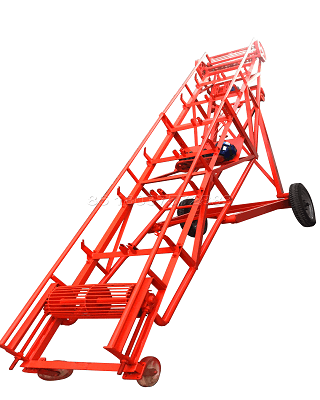

Mobile Fertilizer Belt Conveyor in Stock

- The tape is a rubber product, which should be prevented from coming into contact with oil, gasoline and diesel to avoid corrosion and deterioration and affect the service life.

- Check the operation of the drum, support device, bearing, etc. at any time, and pay attention to whether these rotating parts are flexible, pay attention to add lubricating oil.

- When the belt conveyor is not in use, it should be covered with canvas to avoid sun and rain explosion.

- Under normal circumstances, an overhaul should be carried out once a year.

- Firstly, the feeding device, protective cover and transmission parts should be removed first, then the tape should be removed, and then the supporting device and the roller should be removed, and the cleaning and inspection should be carried out carefully. After the conveyor is installed, make necessary adjustments and then use it.

Applications fields recommendations to belt conveyors

The belt conveyor is a type of continuous conveyor. The continuous conveyor is one of the main types of fixed or transport hoisting conveyors. Its transportation feature is to form a continuous material flow between the loading point and the unloading point, relying on continuous material flow. The overall movement to complete the logistics from the loading point to the unloading point. It can be widely applied in industries, agriculture, transportation and other enterprises.

Fertilizer Belt Conveyor is Being Installed on Indian Fertilizer Plant

Belt conveyors classifications

There are various sorting methods for belt conveyors. The conveyor belt structure for transporting materials can be divided into two types. One type is a common type belt conveyor. In the process of transporting materials in the conveyor belt, the belt conveyor is in the upper belt. Its trough shape and the lower belt are flat. This type conveyor belt is supported by a roller, and the outer shape of the conveyor belt is flat; the other type is a belt conveyor with a special structure.

How to configure the belt conveyor motor?

The working power of your fertilizer conveyor belt machine should be based on your production capabilities requirements. Usually, its working power shall be no less than 500r per minute. When the motor has a rated working power, if you choose a large seize one, it will cost you more. However, its working efficiency is low. If the motor speed is high, the number of pole pairs is small, the size and weight are small, and the price is low. The total motor power required by the belt conveyor is 77.869kw, so it is necessary to select a motor with a power of 90kw. The motor has large torque and good performance, which can meet the material conveying requirements.

How does mobile belt conveyor work?

[embedyt] https://www.youtube.com/watch?v=PQoAo5O82PQ[/embedyt]More details about the compost belt conveyor price, specifications, and configurations, be free to contact us.