As a professional composting equipment manufacturer, we always provide our best solutions and professional quality fertilizer machines for our customers compost production business. In the following contents, there are common questions related to our compost turners’ customers always ask when they choose from our company, and the answers are from our professional sales and engineers.

Q: Your compost turner have the water spray system?(Trench type compost turner for example)

A: in compost production, water or moisture content plays a key role. When the compost materials need additional water supply, timely adding will promote the compost quality and speed up the compost process. In this period, if customer add water manually, it will not quite even. To solve such water supplying problem in composting, when designing a compost turner, we equip a water spray system with our compost turning machine. The water spray system of the compost making machine include two same set (one on the front side, and the other one is on the back side) which is designed for evenly water supplying. And each water supply system is made of the following four parts:

- Water pump

- Steel pipe

- Water spray nozzles

- Water tank

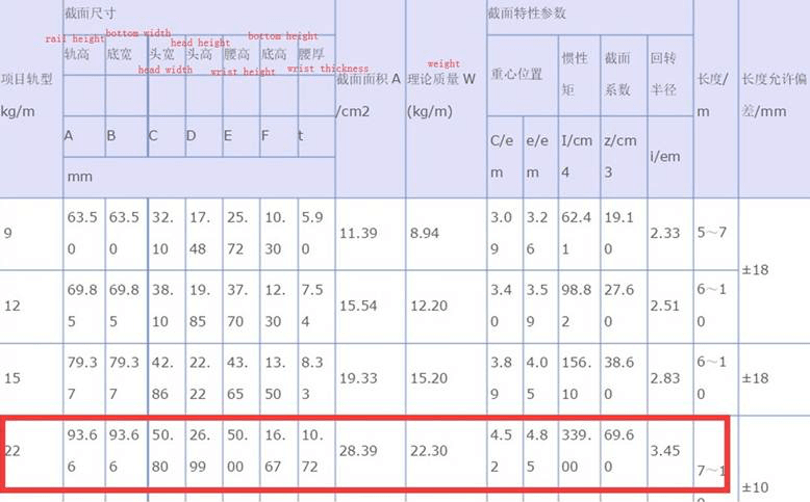

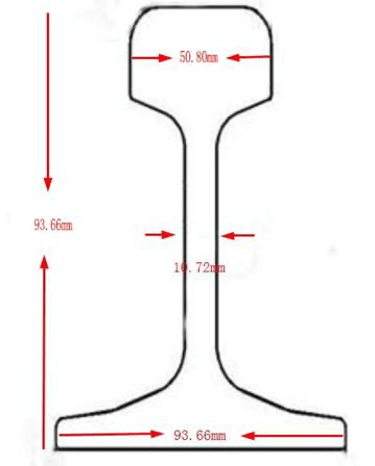

Q: On the compost turner machines price, every one of us want to buy things with less money. However, product quality will always equal to its price. The compost fertilizer manufacturing factory always dedicate itself to making products with quality components and technology. In the trench compost turner machine price, customer always ask: why your rail price is so higher than others’ suppliers?

Different types of compost turner machine price have different quality. Here are our rail details.

One type is: National Standard 22# rail (one meter long rail’s weight is 22kg). Detailed parameters of the groove type compost turner’s rail are as following:

|

|

|

Q: on the compost turner machine specifications, customers who are very familiar with the compost turners always ask the specific sizes of the compost turners they need to buy. Such as: do you have the compost turner machine with 3.2m width and 1 m height?

A: Usually, different types of compost turner machines have different parameters, for the required size of the compost turner, our professional sales recommend the following tow modes of our compost turning machine.

One type is the chain type compost turner machine, specific parameters are as follows:

- SXLDF-2600

- Composting width:2.6m

- Composting height: 1.3-1.5m

- Power:116hp

The other type is the moving type compost turning machine, its technical parameters are as follows:

- SXYDF-3000

- Composting width: 3m

- Composting height: 1.3-1.5

- Power: 136hp

Note: When customer needs specific type of compost turner machines with exact sizes, our professional sales will recommend our best matched composting machines available. If customers need the same sizes for your compost plants, our factory can tailor for you.

Q: on the compost turner machines price, some customer also asks:” what’s your cheapest compost turner?”

A: our moving type compost turner is most cost-effective. As for cost-effective ones of the compost turner machine, customer can choose our compost turner products within their budget. Compared to other types of compost turner machines, such as chain type compost turners, crawler type compost turner machines, wheel type compost turners, the moving type compost turner machine is the most economical one. Customers want to make compost tuners with a limited budgets, can choose this type of low cost compost turning machine.

Q: on products production capacities: what’s the capacity of the compost turner with 116hp?

A: this power is suitable for our SXLDF-2600, its production capacity is 1000 to 1200 m3/h. Different types of compost turners have different capacities, and its power configurations as required.

Q: on land occupations, customers always asked: how many work area does the compost turner need?

A: It depends on the production capacity of the machine. Different capacities of compost turner machines take up different working areas, the larger the capacity is, the more working area of the machine will take up. For the landing area of the compost turner machine, customer can choose the best matched compost turner machines from us based on your own workshop scale.

Q: on the processing materials, customer usually asks: How many raw materials will it need for producing one ton compost?

A: on the production capacity of the compost turner machine needed for raw materials: usually, 3 ton raw materials will have 1 ton finished compost fertilizer. Additionally, the minimum of our compost turning machine is 500 kg per hour. So customers if want to make composts, 2.5 ton per hour processing capacity will be ok to start up the compost production business.

Q: what moisture is it after and before fermentation?

A: 60% moisture before fermentation and 25% to 30% moisture after. The moisture content of the compost turner plays an important role in compost production. If customers raw materials are too high to produce the compost fertilizer, there are also dewatering machines for customer raw materials water removal. During composting, there are also water spray system associated with the compost turning machine to provide available moisture in the compost materials.

Q: on the processing capacities of the compost turner machine, customers always ask: how many can one set of compost turner do?

A: it depend on the capacity of the working area of the compost turner machine. We manufacture different types of compost turner machines with different capacities. Customer can choose them based on the raw material processing capacity they need treatment.

Q: on the compost production times, customer always ask: how many days does the raw materials need for fermentation?

A: 15 to 20 days. From raw materials processing to the finished compost fertilizers, usually it needs 15 to 20 days. Our compost turners with high-working performance can speed up the fermentation process, provide quality composts for you.

Q: on the air-emission of the composting production, customer always ask: does it give out heavy smell?

A: we have quality compost turning machines which can turn organic materials even and timely, let raw materials fully contacted to the air and water, thus in the composting process, it will not have heavy smell.

Q: on the finished compost products forms, people always ask: is it powder after fermentation by the compost turner:

A: yes, the finished compost fertilizer is in powder form. So customer need to make powder fertilizer, one compost turner will be ok. However, there are also some lumps in the composts, so our screeners and crushers will be ok for this.

Q: on the compost turner machine configurations: can we have a cabin on the moving type compost turner?

A: Sure, it needs add additional costs. We can add additional systems to the compost turners based on customers requirements.

Q: on the power system: what is the power? (moving type compost turner)

A: It is diesel type, 30 hp. Different type of compost turners have different power system. Customer can choose our compost turners based on their own power systems. What’s more we can also manufacture the compost turner machine based on customer’s local electricity requirements.

For more detailed information on the compost turners, be free to contact us anytime.