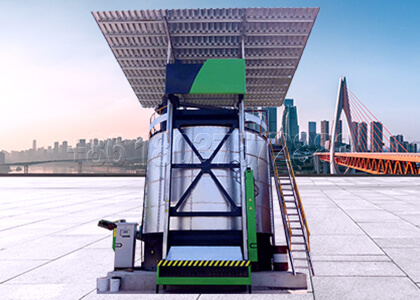

Shunxin compost tank is a compost fermenting machine for organic litters treatments. Organic materials, such as straws, poultry manures, sludges, when processed with shredders, and mixers can be fermented with this compost facility. This fermenter is in a vertical structure. Such design saves your sites space. Customers do not have to invest additional money on the base construction. The tank is a kind of aerobic composting device that integrates waste collection, storage and fermenting functions. It is suitable for small and medium-sized farm manure and domestic garbage disposal in residential areas. The vertical structural, multiple aeration fermenting system will promote your compost manufacturing capability obviously when you facilitate one.

How does the tank ferment organic materials?

This type of compost fermenting facility adopts aerobatic composting technology designed with closed systems, speeding up the raw material fermenting period. The material will be put into the fermentation tank through the feeding hopper driven by the hoisting motor. The general fermentation cycle is about 10 days, so the height direction of the fermentation bin should be divided into 10 equal parts, and the bottom part is fermented 10 layers equally. The top part is the fresh material that was just thrown on the first day. Under the action of the material’s own weight, raw materials can flow into the tank continuously every day, and the lower part is equipped with a discharge mechanism. The stirring motor drives the mixing spindle to realize materials mixing in the warehouse.

A customized compost tank is being shipped to our customers

According to the material requirements, aerobic aeration can be performed every day through the stirring spindle and the stirring arm. All these are specially designed to meet the demand of microorganisms for oxygen. The odor can be collected from the top of the tower for treatment.

Structural highlights of Shunxin fermenting tanks for compost production

- Processing capacity: 2 ~ 10t / d.

- Total installed power:5-30kW.

- Integrating waste collection, storage and fertilizer treatment.

- The reactor is sealed and the amount of odor to be treated is greatly reduced.

- The aeration system is integrated in the agitator, and the oxygen is supplied accurately in the blade mixing place, and the aeration is sufficient and the efficiency is higher.

- Compact structure, no need to build a factory building, small fixed investment

- In the operation room, for organic materials timing stirring and aeration, one device is equivalent to one factory·

How to keep your compost tank work in a continuous higher performance?

Every one of us want to buy a machine with longer service life. As for the compost making facilities, a longer service life tank is quite important for a higher compost throughput. Thus, regular maintenance and timely inspection are vital for a longer service life composting fermenting facility. The following tips in the tank inspection and maintenance just for your reference.

- Check and clean the material adhering to the hopper.

- Before using the gearbox, please check the oil capacity in it. When the tank works about 100 hours, please replace new oil.

- And then using fresh oil every 1000 hours to the gearbox. The maximum time interval is one year.

- Check the oil quantity once a week. When the oil level is found to drop, check for oil leaks, find out the cause, add gear oil.

- When the tank needs to change oil at the lowest oiling level, remove the upper tubing air and drain it from the tank. Rotate the oil plug, collect the oil, and then tighten the drain plug.

- After the hydraulic system is running for 2 hours, all the hydraulic oil should be emptied. And the impurities in the filter of the hydraulic system should be removed. Then, replace the filter element. According to the cleanliness of the discharged hydraulic oil, it is decided whether to reuse or discharge the hydraulic oil after filtration. The cylinder rod should be retracted back into the cylinder; the hydraulic system should be cleaned every 800 hours of operation.

- Lubricate the bearing parts regularly.

Each step you do as the above tips mentioned, will ensure your compost tank work in a higher performance level. Get more details about the tanks design, and prices, be free to contact us.