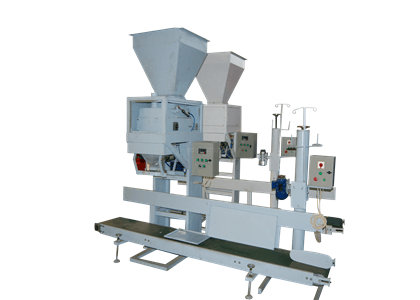

Compost bagging machine is an automatic packing scale mainly used for the metering and packaging of powder or granular materials in compost fertilizer plants. The manure bagging machine is designed with belt feeding device and can weigh compost without bucket configuration. ShunXin manufactured compost packaging scale can process 3 to 50 bags of finished compost per minute. With multi-range measurement function, every compost bag ranges from 20kg to 50 kg.

How to bag compost materials quickly with the packaging machine?

The packing scale enters the automatic running state. When the controller receives the starting information, the bagging mechanism reacts quickly and the clamping material is clamped. The bag is delayed for a period of time, and the controller simultaneously opens the fast feeding valve, and the material falls into the bag. When the weight in the bag reaches the set fast feeding setting value, the feeding speed is transferred to the slow feeding, so that the feeding speed is slowed down. To ensure the accuracy of the weighing, when the material weight reaches the slow feeding setting value, close it, and make a slight delay. When the material in the air reaches the material bag, the bagging mechanism is opened to complete the dynamic weighing process. The set value of slow feeding can be set by yourself according to the fluidity, density and other conditions of the material.

ShunXin granular and powdery compost bagging equipment working performance

- Multi-range measurement, measuring range is 20 to 50kg per bag;

- Automatic folder, sewing bag, packing capacity 3 to 6 packs/min

- High weighing accuracy, measuring accuracy 3/1000;

- Microcomputer control, automatic packaging counting, automatic tare weight and detection function;

- Packaging granular materials should be used for belt feeding. For example, special packaging scales should be used for metering high moisture powder materials.

How does the compost bagging equipment work on our customer’s plant?

Compost self bagging fertilizer machine maintenance tips

- Regular calibration of the scale body, generally, the scale should be calibrated once every six months.

- Eliminate overloading work to avoid damage to the sensor.

- Regularly clean and inspect all parts of the scale body to eliminate the fault in the bud.

- Before use, the gearbox must be checked for oil. After the initial operation for 100h, replace the new oil. Then, change the new oil every 1000h, the maximum time interval is one year.

- When repairing and using the welder in the scale or its surrounding equipment, be careful not to form a current loop between the sensor and the wire.

- Ensure that the equipment and control box have good electrical grounding.

- Ensure that the platform or steel structure supporting the scale body is stable, and do not connect the scale body with the vibration equipment.

- Ensure that the incoming materials are uniform, stable and sufficient; ensure that the gas and power supply are stable and reliable.

- After the end of each day, drain the water from the oil-water separator and refuel regularly.

- The problem should be dealt with in time to avoid the expansion of the fault.

More details about the manure compost bagging machine, be free to contact us.