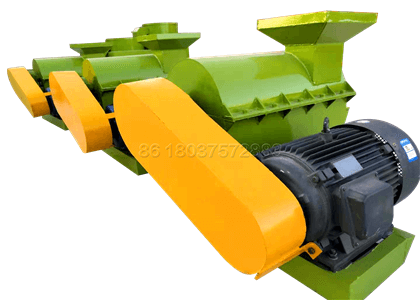

The compost mulcher is suitable for pulverizing organic raw materials with water content below 30% and inorganic raw materials with water content below 12%. The crushing chamber of the mulcher for compost adopts vertical variable diameter structure, and the built-in removable wear-resistant lining plate. It Fis a belt driving vertical hammer mill for compost materials processing. For your compost making facility, ShunXin fertilizer machinery can provide you this hammer mill machine at cost effective price.

How does the compost mulcher press organic materials?

The motor is coupled to the main shaft through a pulley drive system, and the main shaft is supported by the upper and lower end caps of the crushing chamber through the bearings. All these structural design enables you a higher crushing performance compost mulcher.

In order to increase the crushing rate and increase the number of hits in the crushing process, the crushing chamber is designed in a stepped cylinder shape. Three rows of crushing rings are arranged in the crushing chamber. The lower crushing chamber is arranged in two rows of crushing rings. After the crushed material enters the crushing chamber through the feeding ports, it is crushed under the impact of the high-speed rotating crushed chain plate and the collision with the cylinder wall. When the material moves downward due to gravity, the material is successively pulverized and passed through the chain of the upper crushing chamber, and the material enters the crushing chamber. Due to the difference in the diameter of the two pulverization chambers, the falling material falls on the pulverizing plate of the lower pulverizing chamber, and then the pulverized material is pulverized by the two rows of the pulverized material. All these steps ensure the compost fully be crushed. Finally, materials will be discharged through the discharge port.

What’s the machine’s working specification?

ShunXin mulcher shredder machine is a kind of high performance vertical chain hammer mill. It can will be widely used in your garden compost making, kitchen compost production, etc. The machine can crush 1 to 4 tons organic wastes powers. And the crusher also has a high precision crushing fitness, which is less than 3 mmm, accounting for 85%. It can provide ideal forms organic materials for your compost manufacturing reference.

- The cylinder of the commercial compost mulcher is a vertical variable turbulence structure, which is not easy to block and has high pulverization efficiency.

- It has an inspection port for easy replacement of worn parts, and the hammer is a special wear-resistant material.

- The built-in removable wear-resistant lining has low cost of wearing parts.

- Safe and reliable, sturdy and durable, is your ideal compost crusher facility.

How to maintain the machine?

Chain hammer is the most wearable parts in the total compost mulcher. Usually, the hammer can work 6 to 12 months. Additionally., since the machine process materials with strong corrosivity and sticking, regularly check and maintain the machine is quite important. Bearings and triangular tapes are also wearable parts as well as the hammers, maintain and inspect regularly and timely.

- When to use the machine safely: replace the wearable parts, and inspect the total machine. After replacing the new hammer, the hand-cranked spindle is rotated flexibly, and the chain plates of each layer are in contact with the inner wall of the cylinder. After the inspection is completed, the group is crushed. Then, start the main motor, after a certain period of idle operation, if the whole machine runs smoothly, there is no abnormal sound, and it can be used normally.

- How to extend the mulcher’s service life: cleaning and inspection regularly. Check whether there is any residue after starting the machine. If the residual material is discharged, start the crushing motor. After starting for 10 minutes, add the material (requires uniform feeding, no overload work is allowed), then normal operation can be started.

- When to clean materials residues sticky on the wall of the compost mulcher: according to the material and the smashing situation, observe the sticky wall at any time and stop the cleaning. After each shift, the doors on both sides of the crushing chamber should be opened to clean the residual material inside the crushing chamber.

- How to do with the mulchers bears? Bearings should be refueled and cleaned regularly.

- What to do when the triangular tape gets loosen? Triangular tape transmission should always check whether the tension of the tape is appropriate. After the tape is worn, it should be replaced in time.