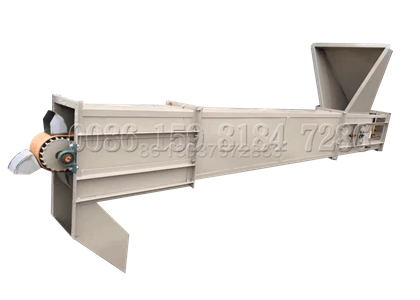

ShunXin fertilizer elevator is suitable for the transportation of powder or granular materials, especially suitable for occasions where the distance between equipment is small. The drive roller of the compost bucket elevator is driven by a squirrel cage, associated with a chain transmission system.

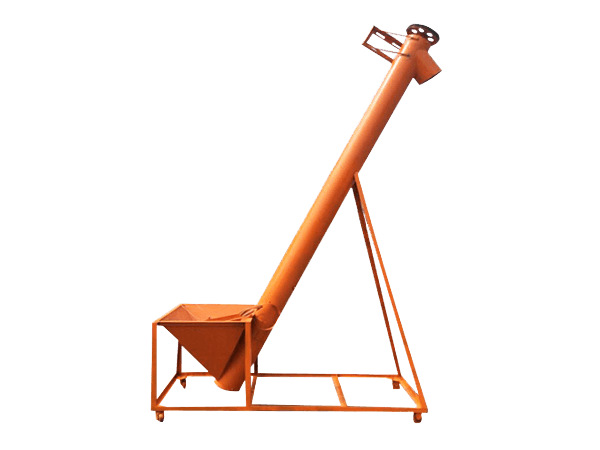

What is the compost elevator’s working principle?

The bucket elevator is a conveying machine that lifts the compost material vertically or nearly vertically by a bucket at a distance from the annular traction member on the driving wheel and the tensioning wheel. The hopper picks up the material from the storage below, as the conveyor belt or chain is lifted to the top, bypassing the top wheel and then flipping down, the bucket elevator pours the material into the receiving tank. The drive belt is generally a canvas belt, and the drive roller mounted on the lower or upper side and the upper and lower reversing rollers are generally equipped with two parallel drive chains, with a pair of drive sprockets above or below. Or above is a pair of redirecting sprockets. Bucket fertilizer elevators are generally equipped with organic shells to prevent dust from flying in the bucket elevator.

Technical performance characteristics of ShunXin brand fertilizer elevator

- Production capacity: 1.0 ~ 10 t / h.

- Supporting power: 1.5~15.0kW;

- Vertical conveying, small footprint;

- Good sealing and eco-friendly;

- Depending on the material characteristics, the bucket can be configured with plastic or iron materials, and the conveyor chain can be configured with a single braid chain, double loop seam or belt type.

When problems occur, how to fix it?

When the bucket elevator is running, ensure that the bucket belt runs in the middle of the barrel. If it is found that there is a deviation phenomenon and the bucket belt is loose and the bucket and the barrel are rubbed, the screw of the tensioning device should be adjusted in time.

- The bucket elevator must be started at no load, the feeding must be uniform, and the discharge pipe must be unblocked to avoid blockage caused by excessive feed or poor discharge. If blockage occurs, the feed should be stopped immediately and the machine should be stopped. The upper board is pulled open to discharge material

- Be careful not to rub it by hand until the bucket can be re-run, then insert the board. In normal operation, it is forbidden to open the hood of the hoist or pump the door.

- The material must be shut down or replaced after the material has been unloaded.

- The residue in the pit of the fertilizer hoist should be removed in time.

- Bearings should be lubricated and cleaned regularly.

- Regularly check the bucket and fasteners. If loose, detached or damaged, it should be tightened or exchanged in time to avoid heavy weight.

- When the machine is shut down for a long time, the discharge door should be opened, the machine memory should be removed, and the door should be closed.

The compost fertilizer elevator is an ideal material transition facility for your fertilizer plants, more details be free to contact us.