The bean dregs dryer is widely used for drying materials in the industries such as distiller’s grains, feed, cassava dregs, soybean meal, fruit dregs, and compound fertilizer production. In order to control the temperature of the dryer, a thermocouple is installed in the feeding and discharging device. The temperature change of the inlet and outlet of the dryer is displayed, and the temperature change of the inlet and outlet of the dryer can be displayed by the temperature, which provides data for better control of the working temperature in the cylinder.

The bean dregs dryer production line is a set of continuous bean dregs drying equipment designed and manufactured specifically for drying the by-product soybean dregs after extraction of soybean protein from soybean meal. Equipment, high and low temperature pipelines, dust removal system, hoisting and conveying system, finished product cooling system, finished product warehouse, electrical control system, steel frame and other equipment and institutions.

Performance characteristics of bean dregs drying equipment

- High degree of mechanization of drying, large production capacity and continuous operation.

- The structure is excellent and simple, the material runs smoothly through the resistance of the cylinder, and the operation is convenient.

- Fewer failures, lower maintenance costs, and lower power consumption.

- The uniformity of product drying.

- The bean dregs drying production line uses a special breaking device to ensure the drying effect of the dryer.

- The novel and unique sealing device, combined with a good thermal insulation system, effectively reduces the coal consumption of the drying system.

- The overall system has good sealing performance, and is equipped with a complete dust removal device, no dust overflow, and a good operating environment.

- The entire drying system adopts electrical centralized control, and the hot air temperature is automatically adjusted, with high degree of automation and easy operation.

- After the drying section, it can be equipped with subsequent sections such as crushing, mixing, granulating, and packaging to produce finished soybean dregs feed.

Bean dregs drying process

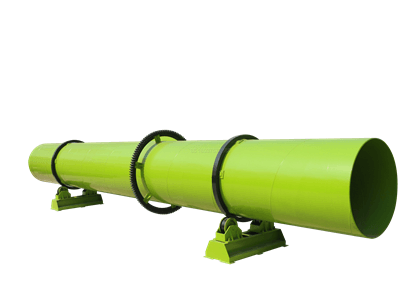

The bean dregs drying equipment is mainly composed of a heating source (hot blast stove or gas stove, etc.), a feeder (disperser), a rotary drying drum, a discharge machine, an induced draft fan, a transmission device, a discharger and a distribution cabinet; After a certain dehydration, the wet bean dregs are dispersed by the feeder into the drying drum, and under the flip of the copyboard and the lifting plate evenly distributed in the drum, they are evenly dispersed in the drying area and fully contact the hot air, which accelerates the drying. Heat and mass transfer; Moisture is extracted by the air induction equipment to prevent the material from returning to moisture. During the drying process, the bean dregs moves to the unloading valve at the other end of the dryer to discharge the dried product uniformly under the action of the inclined plate and the heat medium. In the design of the plan, the characteristics of large moisture content, high protein content, and high viscosity of bean dregs were fully considered, and a series of unique and unique technologies and processes were adopted to solve it to ensure good drying results.

Bean wastes drying machine technical Parameters

| Model(mm) | Angle(%) | Speed(r/min) | Temperature(℃) | Power(kw) | Weight(t) |

| DHф600 | 3-5 | 3-8 | ≤700 | 3 | 2.9 |

| DHф800 | 3-5 | 3-8 | ≤700 | 4 | 3.5 |

| DHф1000 | 3-5 | 3-8 | ≤700 | 5.5 | 5.6 |

| DHф1200 | 3-5 | 3-8 | ≤700 | 7.5 | 14 |

| DHф1500 | 3-5 | 2-6 | ≤800 | 11 | 17.8 |

| DHф1800 | 3-5 | 2-6 | ≤800 | 15 | 22 |

| DHф2000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 28 |

| DHф2200 | 3-5 | 1.5-6 | ≤800 | 30 | 36 |

| DHф2400 | 3-5 | 1.5-5 | ≤800 | 55 | 52 |

| DHф3000 | 3-5 | 1.5-5 | ≤800 | 90 | 65 |

| Note: There is a certain relationship between the output and the heating method | |||||