In Shunxin fertilizer machinery, the company can provide you complete range of compost equipment for your compost line.

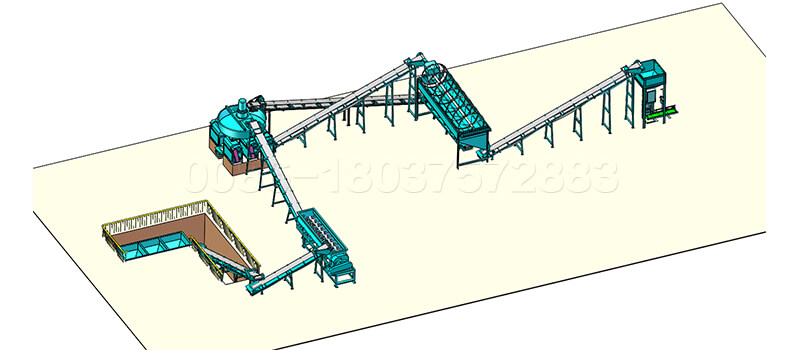

The company can provide you professional solutions meeting your compost production capacity requirements. The following is a compost production line solution from Shunxin fertilizer machinery. This fertilizer production line solution is suitable for spherical (granular) organic-inorganic compound fertilizer production with 3-ton productivity per/hour. The 3-ton compost production line operation and maintenance procedures are as follows.

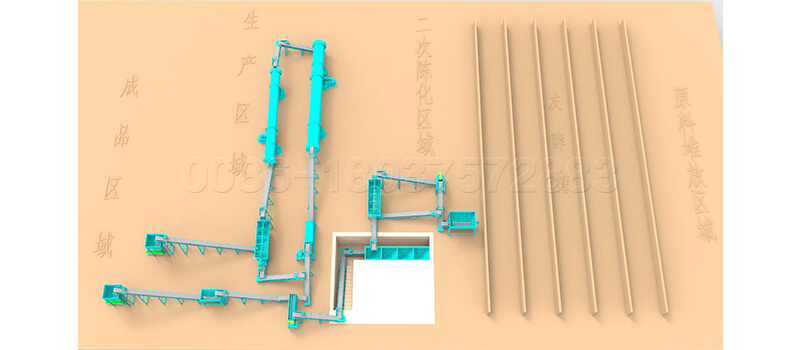

Raw materials pretreatment process for compost producing

It needs 3 people in this material processing process.

One is responsible for straw material mulcher and stocking; One is in charge of chicken manure, and straw material mixing. The last one is responsible for shipping the mixed compost materials into the compost fermenting tank.

Composting fermentation process

It needs 1 person in this process. In this position, the person is responsible for the daily volume and record the temperature of the material in the trough. He is responsible for turning on the turning machine and the aeration system every day.

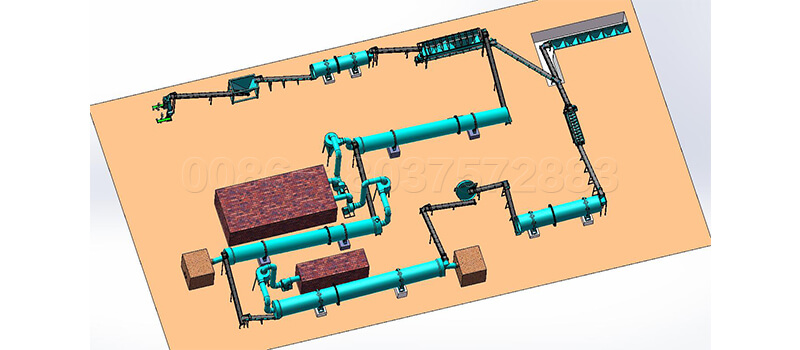

Compost material crushing and screening process

Similar to the fermenting process, it also needs one person in this process.

The worker is responsible for using the loader to inject the material in the fermentation tank into the belt storage bin in front of the crusher;

It is necessary to check regularly whether the compost screener is blocked, whether the inner wall of the pulverizer is bonded; whether the hammer of the pulverizer is worn or not; it is responsible for observing whether the current of the smasher field control cabinet is overloaded.

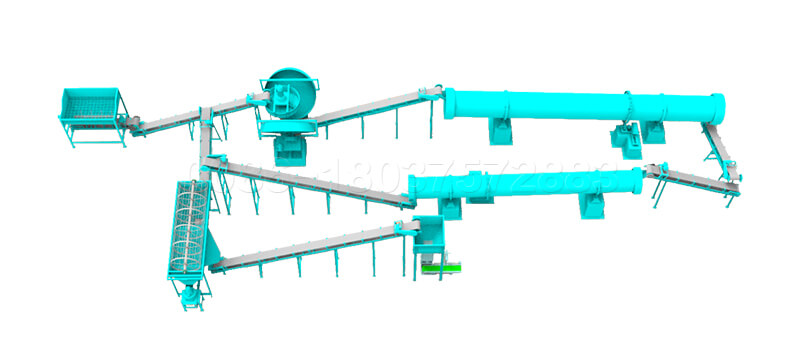

Compost ingredients mixed process

3 people are responsible for this process. The post is responsible for injecting the organic raw materials after crushing. The inorganic raw materials of the powdery tidal deposits piled up between them should be dried and crushed and then injected. It is strictly forbidden to mix the ropes, silk bags and other impurities into the inorganic raw materials.

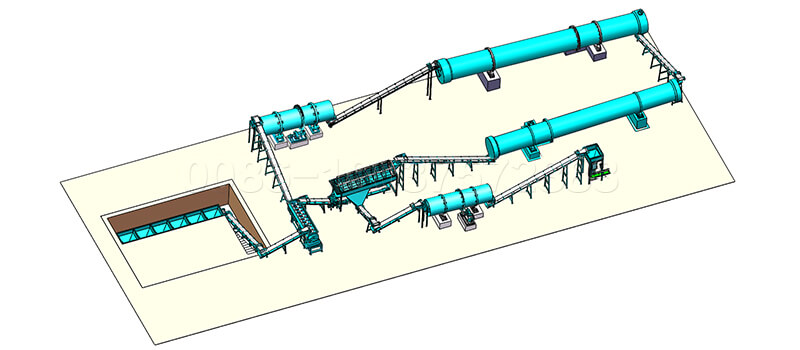

Compost granulation, drying and cooling process

In this production process, it needs 2 people to operate this process. One person should be responsible for adjusting the material quantity of the feeder according to the current situation of the granulator on-site control cabinet; one person should be responsible for the material drying requirements and furnace temperature (drying air temperature after granulation is about 330 °C), timely adding coal to ensure the material after drying to meet the specified requirements and indicators, regularly clean the slag under the grate to avoid excessive slag accumulation and lead to the burning of the grate; the last person is responsible for adjusting the hot air temperature according to the temperature of the material after drying and the discharge amount of the granulator.

Compost screening and packaging process

In this compost production process, it needs compost screeners and compost bagging and packaging machines to finish this production process.

It needs to people to be in charge. One is responsible for observing the blockage of the particle sieving screen; the other is responsible for assisting the electronic packaging machine to bag package compost fertilizer, and to place the metered and packaged material on the transportation device.

In the compost production lines control system center, it also needs one person to operate this process. And it needs another two people to maintain the entire compost production facilities, one for mechanical facility maintenance, and another is for electrical system reparation.

Shunxin fertilizer machinery can provide you complete range of compost production facilities at affordable price. More details about the compost production line in facilities configurations, base constructions, and project solutions, be free to contact us.