Compost pellet machine is a fertilizer granulating machine. It can turn compost fertilizer into pelleted forms. Pellet composts are easy to transport and can also meet fertilizer applicators requirements. At the same time, granular fertilizers the granular material also has a slow release property, creating agglomerate structure for the soil. The granulation method is generally divided into a pellet method and an extrusion method. And the pellet method is divided into a disc system, rotary drum granulation, and extrusion granulation. Moreover, the extrusion method is also divided into flat die granulation and ring die pelletizing. However, the flat die method is not suitable for the organic materials processing due to high processing cost on the mold and the roll, and complicated structure. In ShunXin fertilizer machinery, there are dedicated compost pelletizers for your sawdust, poultry manure, vermin litter granulation, organic materials pelletizing, at affordable price.

Disc granulation for compost pellet making

This type of compost pellet machine is mainly used for ball granulation with good and powdery homogeneous materials. It has a disc structure and gear transmission system.

How does the compost pan granulator work?

The disc granulator rotates at a certain angle (35 degrees to 65 degrees) with the horizontal plane. When rotating, the input compost material rises as the disc rotates, and rolls downward under the force of gravity. The organic material rubs against the bottom of the pan granulator. Meanwhile, the material is smashed toward the edge of the disc due to the centrifugal force. At this time, as the liquid is continuously sprayed to the material through the atomizing nozzle, the material forms a “cue ball” during the rotation and the cue ball increases continuously. Under the collision with the increasing particles during the rotation, the strength of the particles is also continuously increased. When the particles reach a certain amount, under the action of centrifugal force, the edge of the disc overflows to complete the granulation process. ShunXin manufactured pan compost pelletizer has different seizes and configurations both for your fertilizer industry and laboratory experiment applications.

Compost pan pelletizer working performance

- Production capacity: 1.0 to 3.0t/hour;

- Supporting power: 7.5 to 15.0kW;

- Low noise and low cost of wearing parts;

- Intuitive, easy to observe the condition of the granular material;

- The ball formation rate is about 70%, and the amount of return is large;

- In the granulation process, 10%-15% of water needs to be sprayed.

Additional requirements to operate this pan granulator

For your higher throughput granular compost production facility, there are some additional tips for you to operate the pellet machine in a higher performance.

- When making granular with this machine, compost materials should be in a thinner form which should less than 20 meshes. Thus, to reach this requirement, before granulating, it needs compost mulchers to process the materials.

- Compost materials should contain 10% to 15% moisture. Thus, if materials are so dry, it needs to spread water on them.

- After, granulation, the pellet compost needs to be dried with fertilizer driers.

To keep the machine work in a longer time, please check and inspect the pelletizer regularly.

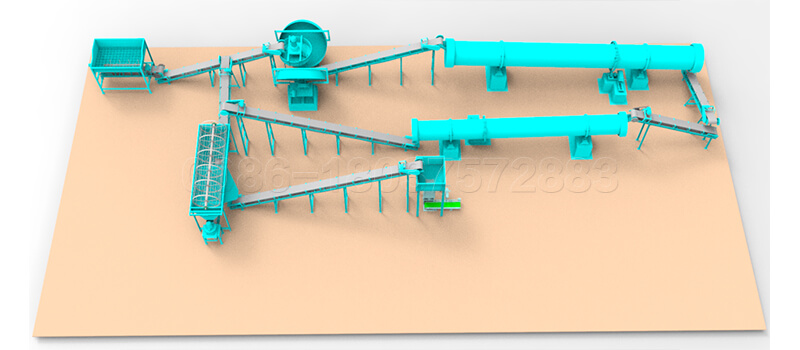

ShunXin brand rotary drum granulation compost machine for sale

It is mainly used for ball granulation with good bonding and uniform material. Different from the pan granulator, it has a drum structure and powered by the gear transmission system.

How to make granular compost with rotary drum pelletizer?

The principle of drum granulation is that the material relies on surface tension, proper liquid phase, and the pressing force generated by rolling between materials, and the material in the correct direction of movement in the granulator is centered on small particles and bonded in rolling ball. When working, the powdery raw material is added to the drum with a certain inclination and slowly rotating after the feeding port. And when the material layer is rotated upward to a certain height by the internal copying board, under the action of gravity and inertia force, the material along the material curved track drops, allowing the material to complete the rolling motion required for granulation. The inside of the cylinder is sprayed on the rolling material layer by steam or water, so that the surface of the fine particles adheres to other fine powders to form a pellet. The material is granulated in the granulation zone, and then passes through the annular retaining ring to enter the light-collecting zone. In the area, the particles are aged and polished, and after the fine particles are grown, they are discharged from the drum outlet. The working performance of this granulator is a bit more complex than the disc pelletizer. However, its granulating rate reaches 60%.

ShunXin rotary drum compost granulator working performance

- Production capability: 1.0 to 6.0t/h.

- Supporting power: 7·5 to 45.0 kW

- The ball formation rate is about 60%, and the amount of return is large.

- In the granulation process, 10% to 20% of water is sprayed, so the finished product must be dried.

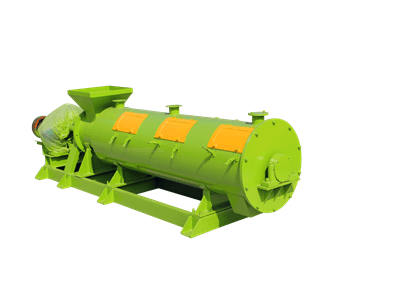

Flat die granulation machine for higher throughput compost pelletizing

The flat die compost granulator is mainly used for extrusion granulation of various organic raw materials. The granulator is constructed with primary gear secondary belt drive system. Its chassis is designed with integral casting technology.

95% compost pelleting rate, a higher performance granulating facility you can count on

The geared motor is the power system of the flat die pelletizer. It mainly uses belt and gear to reduce the power to the spindle. Dynamic scraper, cutter and press roller work. And the pressure roller shaft rotates with the spindle. When the pressure roller and the spindle revolve, the material between the pressure roller and the die is squeezed and rotated, so that the material is rubbed by friction. Particles are formed in the die holes, and as the press rolls continuously move, the particles are continuously formed, and the particles are continuously extruded from the bottom of the die. When the extrusion reaches a certain length, the cutter at the bottom of the die cuts the particles. The particles fall to the ground when the scraper is on the bottom plate, it is transported out of the granulator by the scraper to complete the granulation process.

What is the stunning working performance the flat dite compost pellet making machine?

- Production capacity: 1.0 to 4.0 t / h;

- Supporting power: 22.0 to 90.0kW;

- Material requirements are not high, generally 3 to 4mm;

- The forming rate can reach 95% and the returning amount is minimum;

- The granulation process does not require the addition of moisture;

- The product is cylindrical, smooth and even;

- The flat die is easy to process and can be used on both sides;

- Although the cost of granulating power consumption and accessories is relatively high, there is no need to pulverize the raw materials, no water is added during the granulation process, and its molding rate is high, and the overall production cost is low;

- For spherical particles, it can be used with the rounding machine;

- Calling a good working environment and low labor intensity.

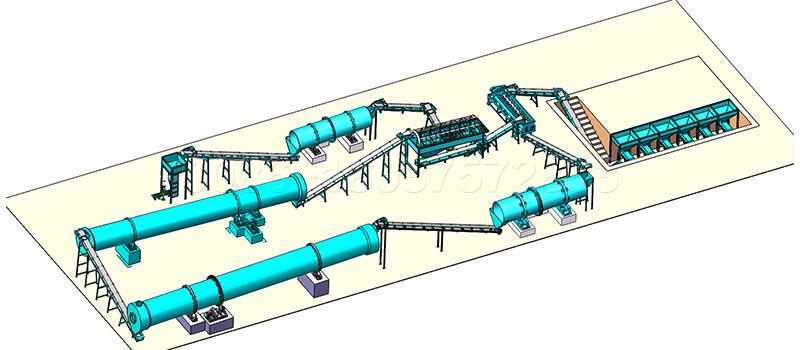

Pan type, drum ones, and flat die ones, which one to choose for your compost plant?

- In price and costs, if you want to choose the cheapest one, pan compost pellet machine will be the perfect one.

- However, if you want to process a large scale of compost plants materials, the rotary drum granulator will be the best one.

- As for the working performance and the granulating rate, flat die compost granulator is the highest among the three types of granulation machines. It is also a dry granulation machine. If you want to buy high compost granular rates machines, the flat die type will be your ideal choice.

In ShunXin fertilizer machinery, any types of compost pellet machine you can share factory price. More details, be free to contact us.