Cow dung manure on the farm will cause bacterial growth if it is not treated in time, and it will also induce some infectious diseases. Now many farms are using cow dung manure dewatering machine and treated by cow dung manure dehydrator. The fertilizer has a high nutrient concentration, is easy to decompose, and absorbs quickly. Then, how is it processed into fermented organic fertilizer?

How to process fermented organic fertilizer with cow dung manure dehydrator?

The following 6 steps in the cow dung manure organic fertilizer production just for your fertilizer making plants reference.

- Preparation of bacteria: Prepare the manure that needs fermentation. It should be fresh cow dung manure (the fermentation effect of fresh manure is better than that of old manure). For example, about 1 ton of fresh cow dung manure plus 0.25 kg of cow dung manure starter must first be mixed with rice bran (or corn flour, wheat bran) at a ratio of 1:5 to 10 for use.

- Cow dung manure piling: the prepared cow dung manure while sprinkling bacteria, should be piled, and the pile height and volume cannot be too short and too small. Requirements: stack height 1.5-2 meters, width 2 meters, length is not limited.

- Adjust moisture. The moisture content of fermented cow dung manure should be controlled at 40-65. Moisture judgment: hold a handful of cow dung manure with your hand, see the watermark on the fingertips but do not drip, and it is appropriate to land. Slow water fermentation, poor water and poor ventilation, can also lead to the smell of spoilage bacteria, so it is necessary to grasp the moisture content.

- Starting temperature. The starting temperature should be better than 15 °C (the four seasons can be operated, not affected by the season, and the winter should be fermented indoors or in the greenhouse), and the fermentation temperature should be controlled below 70-75 °C.

- Mix well ventilation. Cow dung manure starter needs good (consumption) oxygen fermentation. Therefore, during the operation process, oxygen supply measures should be increased to achieve uniform mixing, diligent turning and ventilation. Otherwise, it will lead to anaerobic fermentation and produce odor, which will affect the fertilizer effect.

- The fermentation is completed. Generally, after 48 hours of cow dung manure accumulation, the temperature rises to 50-60 ° C, and the third day can reach 65 ° C or above. At this high temperature, it should be tipped over. Under normal circumstances, there will be two times above 65 ° C during the fermentation process. High temperature, the fermentation can be completed twice, and the fermentation can be completed within one week. The material is dark brown and the temperature begins to drop to normal temperature, indicating that the fermentation is completed.

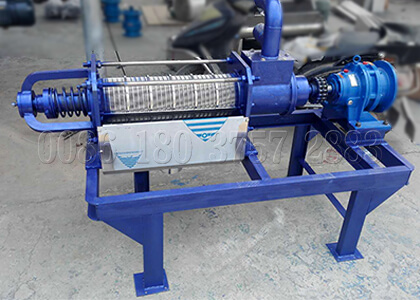

The cow manure dehydrator produced by our factory has the following advantages

- The cow manure dewatering machine produced by our company is made of GB 304 stainless steel and alloy steel. The structural components such as screen mesh are made of nickel alloy steel and high strength carbon steel to ensure the corrosion resistance and strength of the machine. The dewatering machine is very convenient to clean and maintain. When it is used normally, the screen can be cleaned every five months. When cleaning, first remove the bolt of the discharge port, then take out the screen and clean the block with water. When it is clean, so that it can ensure that the processing is smooth and does not cause blockages.

- This series of dewatering machine has high degree of automation, low power consumption, low price, easy to operate, just press the start and stop button, you can operate the machine. It only needs one person. The water content of cow manure feed in summer is between 80% and 90%. After the cow manure is treated, the water content is between 30% and 40%.

How does the cow manure dehydrator work?

- Use the submerged pump to lift the raw manure water to the cow manure solid-liquid separator. The extruded auger will gradually push the cow manure to the front of the body, while continuously increasing the pressure on the leading edge, forcing the water in the material to the side. The mesh screen is extruded under the action of the pressure belt filter, and the drain pipe is discharged.

- The cow manure solid-liquid separator can work continuously, and the material is continuously lifted into the machine body. The pressure at the leading edge is continuously increased. When it is large to a certain extent, the discharge port is opened and extruded. Its wide mouth design is to achieve the purpose of extrusion and discharge.

- If too much fecal water is drawn, it will also be discharged into the original septic tank through the overflow pipe. The waste water separated by spiral extrusion can be directly sent to the sedimentation tank.

How does the cow dung dewatering machine convert the manure from the farm into organic fertilizer?

- In the breeding, we promote the recycling of solid liquid waste from cattle manure sewage in cattle farms, and promote the concept of green environmental protection. We use deep processing of cow manure dehydrator into organic fertilizer. In the past, we used the fermentation products of cattle farms as self-use of farmyard fertilizers, and basically realized harmless treatment and resource reuse. How do different cattle farms produce real organic fertilizer? How to deep-add a commercial organic fertilizer through the cow dung dehydrator.

- The basic principle of organic fertilizer production is to mix organic materials such as excrement and urine with hibiscus and straw, and carry out natural fermentation or microbial aerobic fermentation to convert organic matter into stable humus. Different ways of clearing the dung and processing scale are slightly different. The moisture is an important indicator of organic fertilizer production. Therefore, the dry-cleaning method after treatment by the cow dung dewatering machine and the cow dung processing machine cow dung solid-liquid separator is more suitable for producing organic fertilizer.

- The first step of composting and fermenting is to adjust the water. The most suitable water is 50-60. Excessive or too wet will affect the aerobic fermentation process. After the farm manure is collected by the cow dung dewatering machine, it will be fermented. The first step is to adjust the moisture and C/N ratio to the appropriate ratio by adding high carbon and low moisture excipients. Then, the fermentation method is selected according to the size and site of the cattle farm.

- The complete composting fermentation includes three stages: heating period, high temperature period and cooling period. In the simple case of a general cattle farm, it is mainly carried out in a high temperature period, and the eggs are killed by aerobic fermentation to achieve harmlessness. Aerobic fermentation requires constant tumbling, and conditional cattle farms can use ventilation equipment, a process that typically takes 20 days. The aging time can be long or short, and it can be turned over once a week. If commercial organic fertilizers are produced, it is also necessary to adjust nutrients and moisture to meet industry standards.

The lower layer of biogas residue in the biogas tank can also be used as a raw material for organic fertilizer, but the disadvantage is that the nitrogen volatilization loss is high and the water content is high. For small-scale cattle farms, a certain area of the septic tank can be composted. There are also small fermentation facilities for small-scale cattle farms, but the cost is relatively high. Large-scale cattle farms require larger sites and equipment to produce organic fertilizer.

Windrow composting is a relatively common way to pile up raw materials into strips, underground buried ventilation pipes for intermittent blast supply of oxygen, and turn them up once a day.If it is difficult to meet the standard with cow dung as raw material, it is generally necessary to add some raw materials such as charcoal ash. Or add different proportions of nitrogen, phosphorus and potassium after the fermentation. It is also possible to add functional bacteria and continue to ferment to make various functional organic fertilizers.

The use of cow dung dewatering machine to convert manure into organic fertilizer is the content described above. The use of cow dung dewatering machine is the first equipment in the farm, and it is also the basis for promoting green environmental protection, so that the manure is used here, saving the farm resources.

Operation steps of the fecal dehydration equipment:

- Step 1: According to the wiring prompt of the control cabinet of the dehydration equipment, link the cable.

- Step 2: According to the submerged pump wiring prompt, link the power supply.

- Step 3: Connecting the two ends of the PVC fiber reinforced pipe with the submerged pump outlet and the feed port of the manure dewatering device, and fixing with the hoop tube card.

- Step 4: Check the power supply of the dehydration equipment.

- Step 5: Then, click on the power button (green) to let the dehydration device run.

- Step 6: Turn on the water pump and the power supply to let the water pump start working.

Precautions for the use of fecal dehydration equipment:

- Installation of equipment: The manure dewatering equipment needs to be installed before use. It can be installed according to the actual needs of the breeding site. If installed outdoors, a recommended shelter is required.

- Trial operation: The manure dewatering equipment needs to be tested before use to determine whether the direction of the screw shaft is correct. It is also necessary to adjust the weight to control the humidity of the separator. The manure treated by the manure dehydration equipment cannot be squeezed out by hand, and without chemicals, can feed the fish, or grow vegetables, flowers, tea, etc. as fertilizer.

- The manure dewatering equipment needs regular inspection and maintenance during use, and the machine activity should be added with lubricating oil in time to make the equipment run better.

- In order to prevent clogging, the tail of the dewatering equipment is convenient for discharging. Generally, the open discharge is adopted, that is, the safety protection net is not installed at the discharge part, so do not put your hand into the solid discharge port during the operation of the equipment.

- The power of the fecal dehydration equipment will generally use 380v power supply, pay attention to safety during operation and prevent electric shock.

- The filter screen of the dewatering equipment needs to be cleaned every 15 times to ensure the filtrate effect of the filter and the low water content of the extruded solid.

Wearable parts replacement suggestions

- During the long-term operation of the dehydrator, it is normal for the internal wear to have different degrees of wear. This requires us to inspect and maintain the internal parts in time during use, and eliminate the safety hazards in the bud. Therefore, the normal use of the dehydrator is guaranteed. In view of this, our dewatering machine manufacturer will give you a detailed introduction of the replacement cycle of the internal vulnerable parts, which is convenient for everyone to use later.

- Dehydrator tug shaft. During the operation of the dehydrator, the carrier is the core component that supports the weight of the entire device. With the long-term drying operation, the wear of the roller is inevitable when the roller shaft of the dehydrator is worn 20, or the thickness of the roller rim of the roller and the wheel is worn away by 25, or the rim is ground into a conical shape. When the surface of the belt is ground into a cone, a polygon, and a local penetration crack, it must be replaced in time.

- The transmission gear is one of the parts that are easy to wear in the dehydrator. When the gear or the large ring gear wears 30 or 0.5 modulus, the edge of the gear is seriously worn and cannot be repaired. If there is serious wear or breakage of the gear ring of the machine, it is necessary to contact the manufacturer after sale and replace it properly under the guidance of professional technicians.

- When the dehydrator is used to dry the wet cow manure, it is realized by heat exchange between the high-temperature air stream and the wet material. If we use the dehydrator, we do not strictly follow the correct use of the equipment and the sequence of the switch, which will cause cracks or local deformation of the dryer cylinder. At this time, we need to repair or replace the dehydrator cylinder with cracks or deformation.

Technical characteristics of the dehydrator:

- Leading separation technology: The dewatering machine adopts the organic combination of spiral pressure and dynamic, static ring to form a new separation technology of dehydration and concentration integration, which adds a new dehydration mode to the field of environmental protection wastewater treatment.

- Energy saving, water saving: the dynamic and static ring of the dehydrator continuously shifts to the self-cleaning effect in the cylinder body, achieving the purpose of not blocking the filter gap, replacing the high-pressure flushing of the old filter cloth and the belt filter plate, saving industrial water (Single machine water saving 13,000 tons per year), the low speed of the main screw shaft (3-5 rpm) reduces the mechanical wear of the equipment, prolongs the service life of the equipment, the power consumption of the main unit is 1.1kwhr, and the power consumption of the single machine reaches 50,000 degrees.

Cow Dung Dewatering Machine Main Technical Parameters (Screw Press Type)

| Model | Capacity(CBM/Hr) | Power(kw) | Dimensions(feet) |

|---|---|---|---|

| SXTS-180 | 10~15 | 4 | 6*2*4 |

| SXTS-230 | 15~20 | 5.5 | 6*3*4 |

Cow Dung Dewatering Machine Technical Specifications (Inclined Type)

| Model | Capacity(CBM/Hr) | Power(kw) | Dimensions(feet) |

|---|---|---|---|

| SXTS-800 | 15~20 | 4 | 5.6*4.9*4.3 |

| SXTS-1200 | 30~40 | 5.5 | 7.2*4.9*5.6 |

Notes: The above are main technical data of popular sale type solid liquid separators, more details and other additional capacities you need, welcome contact us for quotations.

Q&A related to manure dewatering machine

Shunxin compost fertilizer machinery can provide customers a complete range of processing facilities for quality compost production. The solid-liquid separator is a pre-compost machine to control the moisture content of organic manure materials. The following questions and answers are common seen solutions related to manure dewatering machine in application and services we can provide. Any other questions you have, welcome e-mail us at any time.