Cow Dung Fertilizer machines in organic fertilizer production line

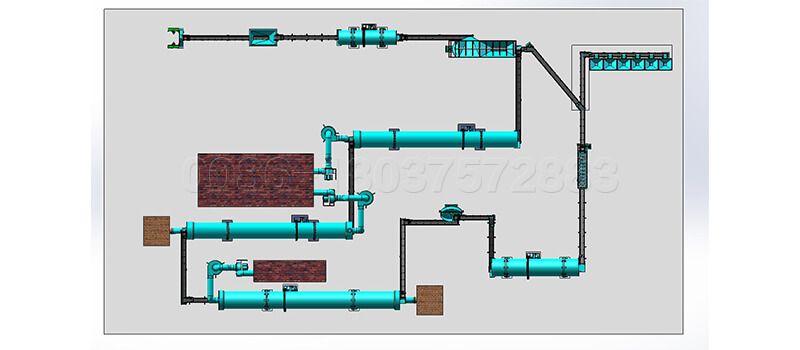

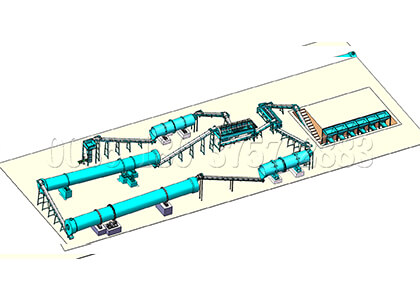

To make organic fertilizer from cow dung or turn cattle manure into organic fertilizer, it needs different manure treatment machines in different manure production processes, which includes dewatering process, composting process, cow dung compost pellet making process, manure screening process, pellets cow dung composts drying, cow manure compost granules cooling, and finished cow dung fertilizer packaging. Detailed information about cow manure fertilizer machine configurations in different manure fertilizer production processes:

In the first cattle dung fertilizer production process, it needs removing water from cow dung, so customers need solid liquid separator to dewater the cow dung, our cow dung dewatering machine can dry cow dung to 30% to 45% which can meet the requirement of manure composting.

The second manure management process is the dewatered cow dung composting process. In this production process, customer need to configure a compost making machine or compost turner for your cow dung fertilizer production line.

How to compost cattle manure or how to make compost from cow dung?

When composting cattle manure, customers need to combined cattle dung with bovine urine, to make high quality cow manure composts, add dry grasses and rotten green wastes will be better. To speed up the cow dung compost production process. For customer’s compost production process, we have different types of compost turner machines such as:

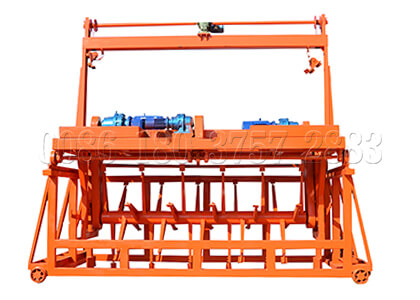

Moving type compost turners for cattle manure production

This type of portable compost turning machine has production capacity from 800 cubic meters per hour to 1000 cubic meters per hour. Except for cattle manure composting, this type of compost turning machine are also available for chicken manure, sheep manure, pig manure and other animal manure and farm plant wastes compost production.

The walking type composting machine (self-propelled composting machine) is the main machine in the complete set of equipment for producing bio-organic fertilizer. The machine adopts a four-wheel walking design, which can move forward, backward, and turn, and be controlled by one person. During driving, the whole vehicle rides on the long-stacked fertilizer base, and the rotating knife shaft mounted under the rack is used to mix, fluff, and move the fertilizer-based raw materials. After the vehicle passes, it is tampered with new bars. Shaped pile. This can be done in open areas or in workshop sheds.

Moving Type Compost Turner for Cow Dung Composting Working Performance

- The fermentation process of this type of cow dung fertilizer machine, adopts microbial aerobic fermentation, which is designed according to the principle of aerobic fermentation, so that the fermenting bacteria have room to fully perform its functions.

- It can effectively mix viscous cattle manure with microbial preparation and straw powder, creating a better aerobic environment for material fermentation.

- The whole machine has suitable power balance, low energy consumption and large output, which reduces the production cost of biological organic fertilizer.

Working principle of the cow dung moving compost turning machine:

This equipment uses a diesel engine as the power source, transmits motion through the power transmission, uses a machete to rotate the material, and the driver controls the work of the stacker. The scope of application of the cow dung composting machine:

- Bar pile: the width cannot exceed the equipment width, the height can be increased within 100mm, and the length is not limited.

- There should be no less than 10 meters of empty space at both ends of the pile to facilitate turning, and the distance between the piles should be more than 1 meter.

- This machine is only a walk-over dumping machine, and cannot be used as a walking vehicle or a heavy-duty vehicle.

- The work area must be on a flat surface, and the ground must be a concrete ground.

Moving Type Cow Dung Compost Turner Specifications

| Model | XZFPJ2000 | Power | 27.5HP |

| Composting Width | 2000MM | Heights | 600-800MM |

| Working Span | 600-800MM | Particle Size | 250MM |

| Roller Dia. | 600MM | Production capacity | 400-500CBM/HOUR |

| Sizes | 2100*2600*2700mm | Weights | 1500KG |

Chain Type Cow Manure Compost Turner Machine

- Brief-introduction: Production capacity:10-20t / h

- Applicable materials: Can be used for livestock and poultry manure, sludge garbage, sugar filter sludge

- Application Fields: This type of compost turner is suitable for trough aerobic composting of organic solid waste such as livestock and poultry manure, sludge garbage and straw.

Chain plate compost turner is suitable for trough aerobic composting of organic solid waste such as livestock and poultry manure, sludge garbage and straw. The traveling system of the machine adopts the advantages of variable frequency speed regulation, good adaptability to different materials, stable operation, high stacking efficiency, and deep groove operation, which can effectively shorten the fermentation cycle, improve production efficiency and product quality. Adopting frequency conversion speed control speed walking system, can adapt to the change of workload well. The walking speed can be flexibly adjusted according to the material resistance, so that the equipment has stronger adaptability and flexibility. Optional moving vehicles can be used to realize the use of multi-tank equipment. When the capacity of the equipment allows, simply adding a fermentation tank can expand the production scale and increase the value of equipment.

Why most customers choose this type of compost turning machine for their cow manure fertilizer production line?

- It adopts the chain transmission and rolling support pallet structure, which has small resistance to flipping, saves energy and energy, and is suitable for deep groove operation.

- The flipping pallet is equipped with flexible tensioning and elastic shock absorption systems to protect the efficient operation of the transmission system and working parts.

- The flipping pallet is equipped with a removable wear-resistant curved tooth blade, which has strong crushing ability and good oxygenation effect.

- When turning over and composting, the material stays on the pallet for a long time, it is scattered at a high position, it is in full contact with the air, and it is easy to get water.

- Through horizontal and vertical displacement, it can realize the flipping operation at any position in the tank, which is flexible and flexible.

- The lifting and lowering of the working parts is controlled by a hydraulic system, which is flexible and safe and fast.

How does the chain type compost turner make cow dung compost?

The organic fertilizer fermentation process of the cow manure fertilizer production line is mainly mixing organic waste such as livestock and poultry manure with fermenting bacteria and auxiliary materials (water content is 50-60%), and sending it to the front of the fermentation tank with a forklift (1/8 of the original empty tank front or The front end of the tank vacated after turning over the stack 1/8), the fermentation material accumulates in the tank with a thickness of 1.5-1.6 meters, and is continuously aerobic fermented by the high pressure fan for forced ventilation and the oxygen provided by the material in contact with the air during turning over the stack to make the fermentation fast rot, dehydration and drying, fermentation cycle is 7-8 days. Under the action of the vertical and horizontal walking mechanism, the multi-toothed plate structure conveyor scraper at an angle of 45 degrees to the bottom of the pool continuously and gradually picks up the fermentation material and transports it to a high point along the bottom of the pool, and then composts it back into the Heap and generated displacement. After turning over the pile twice a day, the whole process of continuous aerobic fermentation is completed. Fermented materials (processing capacity, 1/8 of the tank length) are removed from the end of the fermentation tank with a forklift every day, and the space (processing capacity, 1/8 of the tank length) vacated at the front of the fermentation tank is supplemented with new fermentation materials. Thus, it forms a continuous fermentation process. After leaving the pond, the materials are piled into a pile and stored for secondary fermentation (10-15 days) to further rot and remove some water.

Ø The use of a chain drive and rolling support pallet structure, small flip resistance, saving energy and energy, suitable for deep groove operation.

Ø The flipping pallet is equipped with flexible tensioning and elastic shock absorption systems to protect the operation of the transmission system and working components.

Ø 390 pieces of wear-resistant curved tooth cutters are installed on the turning and composting pallet, which has strong crushing ability and good oxygenation effect.

Ø When flipping and composting, the material stays on the pallet for a long time, it is scattered at a high position, it is in full contact with the air, and it is prone to precipitation.

Ø Through horizontal and vertical displacement, it can realize the flipping operation at any position in the tank, which is flexible and flexible.

Ø The lifting of the turning and composting working parts is controlled by a hydraulic system, which is flexible and convenient.

Ø It can remotely control the machine’s forward, traverse, flip and fast backward operations to change the operating environment.

Ø Optional trough raw material distributor, automatic discharge device, solar fermentation room, ventilation and aeration system, etc.

Ø Equipped with a moving machine to change the slot can realize one slot turning machine with multiple slots, saving investment.

Technical Parameters of cow dung fertilizer machine for cow manure processing machine:

| Model | SXLFP38 | SXLFP38 | SXLFP38 |

| Power(kW) | 31.55 | 31.55 | 31.55 |

| Width of flip chain plate(mm) | 2000 | 2000 | 2000 |

| Materias Heights(mm) | 1800 | 1800 | 1800 |

| Working speeds(m/h) | 120 | 120 | 120 |

| No-load speed(m/h) | 300 | 300 | 300 |

| Production Capacity(m3/h) | 432 | 432 | 432 |

| Span (m) | 3~4 | 3~4 | 3~4 |

| Hoist Heights(mm) | 4250 | 4250 | 4250 |

| Fermentation tank width (track center distance) (m) | 4.40/6.40/8.40 | 10.40/12.40/14.40 | 16.40/18.40/20.40 |

| Fermentation tank heights (mm) | 2000 | 2000 | 2000 |

Trench Type Compost Turner for Cow Dung Compost Production

How to compost cow manure in trench?

The trench type compost turning machine is also commonly referred to as a rail type compost turning machine. It can be used for livestock and poultry manure, sludge garbage, sugar mill filter sludge, lees

fermentation of organic waste such as slag cake meal and straw sawdust, widely used in organic fertilizer plants, compound fertilizer plants, sludge waste, plants, horticultural fields, and agaricus plantations, etc.

Technical Highlights of the cow dung compost fertilizer production machine

- It is suitable for aerobic fermentation, and can be used in conjunction with solar fermentation chambers, fermentation tanks and moving machines;

- It can be used with the travelling machine to realize the function of one machine with multiple slots;

- The matching fermentation tank can discharge continuously or batches;

- High efficiency, stable operation, sturdy and durable, even turning and composting;

- Control cabinet centralized control, can realize manual or automatic control function;

- Equipped with soft starter, low impact load when starting;

- Equipped with gear hoisting hydraulic lifting system;

- The teeth are strong and durable, and have certain shattering and mixing functions for materials;

Trench type compost cow manure turning machine configuration:

Main configurations of the compost turning machine:

- It includes a walking fermentation tank body, a walking track, a power take-off device, a dumping and dumping part, and a rotating tank device (also called a transfer vehicle)

- It is mainly used in the case of multi-slot use). The working part of the dumping and dumping pile adopts advanced roller transmission, which can be lifted and can’t lift both.

Special configurations for high quality and efficient cow dung production:

- The control cabinet has centralized control, which can realize manual or automatic control functions.

- Equipped with soft starter, low impact load when starting.

- Equipped with a gear lifting hydraulic system.

- The teeth are sturdy and durable, and have certain shattering and mixing functions for materials.

- Limit travel switch for safety and limit function.

Technical Parameters of Cow dung fertilizer compost machine:

| Model | SXCFP3000 | SXCFP4000 | SXCFP5000 |

| Power(KW) | 18.5+3+2.2 | 18.5+3+2.2 | 22+3+2.2 |

| Walking Speed(M/H) | 50 | 50 | 50 |

| No-load Speed(M/H) | 100 | 100 | 100 |

| Fermentation Tank Size (mm)(W*H) | 3000*1050 | 4000*1050 | 5000*1050 |

| Stirring-teeth hoisting heights(mm) | 1000 | 1000 | 1000 |

Crawler Type Compost Turner for Sale

Crawler-type compost turning machine is a kind of large-scale compost turning machine, full hydraulic operating system, lever-type steering wheel operation, track-type walking, sturdy and durable, strong power, advanced technology, large output, strong flipping ability, hydraulic lifting of flipping drum Adjustment, high degree of automation, simple operation and easy to master. It is a special turning equipment for converting organic materials into oxygen by aerobic fermentation.

Product advantages:

- The operation is easier, the hydraulic directional type is eliminated, the space, labor and diesel are saved, the working time is shortened, and the fermentation cycle is advanced.

- This product adopts soft start to turn the clutch. (Similar products use iron-to-iron hard clutch, which seriously damages the chain, bearing and shaft). The front hydraulic push plate is installed, which eliminates the need for time-consuming whole stacks.

- The drum is hydraulically lifted, and the cabin can be equipped with air conditioning.

| Model | SXLF-2400 | SXLF-2600 |

| Turning Width(mm) | 2400 | 2600 |

| Turning Heights(mm) | 600-800 | 1000-1300 |

| Windrow Span(mm) | 800 | 800 |

| Particle Size(mm) | 250 | 250 |

| Power | 4102 turbocharged 75 hp | 4108 turbocharged116 hp |

| Speed(r/min) | 2400 | 2400 |

| Rated Speed(r/min) | 2400 | 2400 |

| Working Speed(m/min) | 6-10 | 6-10 |

| Walking Speed(m/min) | 50 forwards and 6 speeds | 50 forward 6 speeds, 1 reversea |

| Stirring-teeth Dia.(mm) | 600 | 600 |

| Production Capacity(m3/h) | 500-700 | 700-1000 |

Wheel plate type Composting Machine for Cattle Dung Compost Production

Top 5 stunning features customers choose our wheel type compos turner:

- High composting depth: the composting depth can reach 1.5-3m.

- Large composting span: the composting width can reach 30 meters.

- Low energy consumption of tipping: the unique energy-saving transmission mechanism is adopted, which reduces energy consumption by 70% compared with traditional tipping equipment under the same workload.

- Flipping without dead angle: the wheel disc shall be flipped symmetrically without dead angle under the displacement of speed regulating and shifting trolley.

- High degree of automation: equipped with fully automatic electrical control system, no personnel operation is required during the working period of the equipment.

Technical parameters:

The wheel plate type compost turning machine is also a leaf wheel type. The width of the machine is 15m (the specific width can be customized according to the user’s requirements), the depth of the materials to be dumped is 3000mm, and the length of the fermentation tank is 50-200m (the length can be customized according to the user’s site).

How to operate the wheel type compost fertilizer machine?

The machine has the function of automatic operation. Users only need to press the start button.

Packing list:

- One main machine of wheel plate type tipping machine

- One set of automatic conveying system

- A set of automatic distribution system

- One set of intelligent control cabinet

Where you can use the wheel type compost turning machine for cattle manure compost making?

Applicable materials: it can be used for livestock and poultry manure, sludge waste, sugar factory filter mud

Application scope: it is widely used in fermentation, ripening and water removal operations of organic fertilizer plants, compound fertilizer plants, sludge and garbage plants, horticultural fields and Agaricus bisporus planting plants.

The above information is just a brief introduction to the machines used for cattle manure compost fertilizer production.