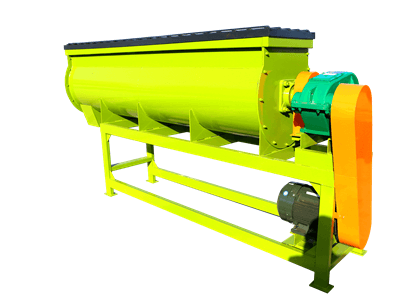

Single shaft mixer for cow manure compost mixing

The single-shaft mixer is mainly used in organic fertilizers production lines, compound fertilizers and dust collectors of thermal power plants. It can also be used in chemical metallurgy, mining, building materials and other industries.

The use and advantages of the machine

It is mainly used in organic fertilizers, compound fertilizers and dust collectors of thermal power plants.

The advantages of single fertilizer shaft mixer are:

- It has high mixing efficiency and small floor area. Spiral blades are made of high-wear-resistant special alloys.

- The single-shaft mixer is driven by a reducer, with smooth rotation and low noise.

- The single-shaft mixer feeds from the top and discharges from the bottom. The structure is reasonable.

- Tight seals between each joint surface and smooth operation.

Working performance of single shaft fertilizer mixer

- Efficient. It has high mixing efficiency and small footprint. Spiral blades are made of high-wear-resistant special alloys.

- Low noise. Adopting reducer transmission, the rotation is stable and the noise is low.

- Reasonable structure. The single-shaft mixer feeds from the top and discharges from the bottom. The structure is reasonable.

- Running smoothly. The seals between the joint surfaces are tight and the operation is stable.

Single shaft cow dung compost mixing machine working principle

The single-shaft mixer uses a shaft equipped with a spiral blade to rotate. When conveying powdery materials such as dry ash, it is stirred by adding water to uniformly humidify the dry ash powdery material, so that the humidified material does not escape dry ash and does not leak water droplets.

Technical Parameters of single shaft manure mixing machine

| Model | Size | Power | Thickness | Reducer Model | Speed |

| SXSJ-7030 | 4000*950*1600mm | 11kw | 4mm | ZQ350-23.34 | 54r/min |

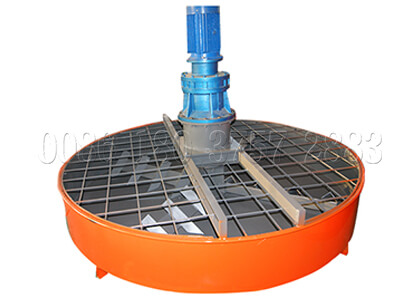

Disc mixer of cow manure compost mixing

The disc mixer is a new type of fertilizer equipment improved on the basis of the original compost mixer. It is mainly used in organic fertilizers, compound fertilizers and dust collectors of thermal power plants, and can also be used in chemical metallurgy, mining, building materials and other industries.

The use and advantages of the disc fertilizer machine

It is mainly used in organic fertilizers, compound fertilizers and dust collectors of thermal power plants. It can also be used in chemical metallurgy, mining, building materials and other industries.

The advantages of disc mixer are:

- It has high mixing efficiency and small floor area. Spiral blades are made of high-wear-resistant special alloys.

- The disc mixer is driven by a reducer, which rotates smoothly and has low noise.

- The disc mixer feeds from the top and discharges from the bottom. The structure is reasonable.

- Tight seals between each joint surface and smooth operation.

- Disc fertilizer mixer machine working performance

- High efficiency, using high wear-resistant alloy. It has high mixing efficiency and small footprint. Spiral blades are made of high-wear-resistant special alloys.

- Low noise. The disc mixer is driven by a reducer, which rotates smoothly and has low noise.

- Reasonable structure. The disc mixer feeds from the top and discharges from the bottom. The structure is reasonable.

- Running smoothly. The seals between the joint surfaces are tight and the operation is stable.

- The disc mixer motor drives the reducer, the reducer drives the main shaft, and the main shaft drives the stirring teeth to stir the material.

Technical Parameters of disc type fertilizer crusher

| Model(m) | Size (mm) | Heights(mm) | Dia.(mm) | Motor(kw) | Reducer Model | Speed(r/min) | Main Body Thickness(mm) | Bottom Board Thickness(mm) | Capacity(t/h) |

| SXPJ-1600 | 1600×1600×1800 | 400 | 1600 | 7.5 | BLD15-87 | 16 | 5 | 8 | 2-4 |

| SXPJ-1800 | 1800×1800×1800 | 400 | 1800 | 7.5 | BLD15-87 | 16 | 5 | 8 | 3-5 |

| SXPJ-2000 | 2000×2000×1800 | 400 | 2000 | 7.5 | BLD15-87 | 16 | 5 | 8 | 4-6 |

| SXPJ-2200 | 2200×2200×1850 | 400 | 2200 | 7.5 | BLD15-87 | 16 | 5 | 8 | 6-8 |

| SXPJ-3000 | 3000×3000×2000 | 400 | 3000 | 15 | XLD9-87 | 16 | 5 | 8 | 8-12 |

Double shaft mixer for manure compost mixing

The double-shaft wet mixer is a new type of equipment improved on the basis of the original mixer. It is mainly used in organic fertilizers, compound fertilizers and dust collectors of thermal power plants, and can also be used in chemical metallurgy, mining, building materials and other industries.

Double shaft fertilizer mixer for cow dung fertilizer mixing

It is mainly used in organic fertilizers, compound fertilizers and dust collectors of thermal power plants. It can also be used in chemical metallurgy, mining, building materials and other industries.

The advantages dual-shaft wet mixer are:

- It has high mixing efficiency and small floor area. Spiral blades are made of high-wear-resistant special alloys.

- The dual-shaft wet mixer is driven by a reducer, with smooth rotation and low noise.

- The double-shaft mixer feeds from the top and discharges from the bottom. The structure is reasonable.

- Tight seals between each joint surface and smooth operation.

Performance characteristics of double shaft fertilizer mixing equipment

- High efficiency, using high wear-resistant alloy. It has high mixing efficiency and small footprint. Spiral blades are made of high-wear-resistant special alloys.

- Low noise. The disc mixer is driven by a reducer, which rotates smoothly and has low noise.

- Reasonable structure. The disc mixer feeds from the top and discharges from the bottom. The structure is reasonable.

- Running smoothly. The seals between the joint surfaces are tight and the operation is stable.

- The dual-shaft mixer uses the synchronous rotation of two symmetrical spiral shafts to add powder and dry powder while mixing with water to stir and dry the powdered material evenly.

Technical Parameters of double shaft fertilizer mixer

| Model | Power | Reducer Model | Dia. | Speed | Size |

| SXSJ-8030 | 11kw | ZQ350-31.5 | 420mm | 35r/min | 3700×800×750mm |

| SXSJ-1050 | 22kw | ZQ500-31.5 | 650mm | 35r/min | 6200×1300×1200mm |

Horizontal mixer for cow dung compost mixing

Horizontal mixers are mainly used in organic fertilizers, compound fertilizers and dust collectors of thermal power plants, and can also be used in chemical metallurgy, mining, building materials and other industries.

.jpg)

The use and advantages of the machine

It is mainly used in organic fertilizers, compound fertilizers and dust collectors of thermal power plants. It can also be used in chemical metallurgy, mining, building materials and other industries.

The advantages of horizontal mixer are:

- It has high mixing efficiency and small floor area. Spiral blades are made of high-wear-resistant special alloys.

- The horizontal mixer is driven by a reducer, with smooth rotation and low noise.

- The horizontal mixer feeds from the top and discharges from the bottom. The structure is reasonable.

- Tight seals between each joint surface and smooth operation.

Horizontal compost mixing equipment working performance

- High efficiency, using high wear-resistant alloy. It has high mixing efficiency and small footprint. Spiral blades are made of high-wear-resistant special alloys.

- Low noise. The disc mixer is driven by a reducer, which rotates smoothly and has low noise.

- Reasonable structure. The disc mixer feeds from the top and discharges from the bottom. The structure is reasonable.

- Running smoothly. The seals between the joint surfaces are tight and the operation is stable.

- The horizontal mixer uses a shaft equipped with a spiral blade to rotate, while mixing powdered materials such as dry ash, and adding water to stir, evenly wet the dry ash powdery material, so that the humidified material will not dry out the ash and will not seep water droplets. purpose.

Horizontal fertilizer compost mixer technical parameters

| Model | Power(kw) | Reducer Model | Speed(r/min) | Main Body Thickness(mm) | Capacity(t/h) | Size (mm) |

| SXWJ-7015 | 7.5 | ZQ350-23.34 | 46 | 4 | 2-3 | 2350×1200×1000 |

| SXWJ-9015 | 11 | ZQ350-23.34 | 39 | 4 | 3-5 | 2350×1200×1000 |

| SXWJ-1630 | 22 | ZQ500-48.57 | 21 | 10 | 10-15 | 3950×1720×2100 |