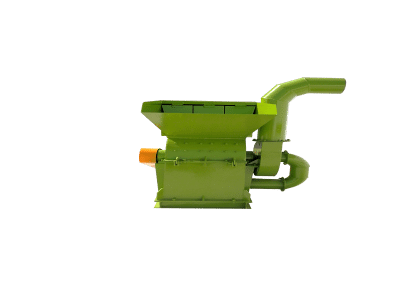

Straw grinder for sale

The straw grinder is another new product of our company in the wood flour mill market. This product can guarantee the standard rate of finished products, solve the inconvenience caused by unevenness of finished products, and prepare standard stainless steel internally.

Fertilizer crusher for straw crushing

- Screen, random selection of mesh, standard, small footprint, convenient packaging, simple operation, no dust pollution, is the ideal milling equipment.

- This product has reasonable design, reliable manufacturing quality, simple structure, convenient operation, small size, small footprint, labor saving and power saving.

- The designed fully automatic control electric heating device can randomly adjust the dry and humidity of the material, ensure the stability of the material forming, and improve the work efficiency.

- The main parts of this product are made of abrasion-resistant materials and undergo special treatment, so they can be continuously pressed for powderr straw production.

- Suitable for all kinds of biomass raw materials (corn straw, wheat straw, cotton stalk, straw, branches, leaves, sawdust and other agricultural bits as raw materials

Straw pulverizer working principle

The straw pulverizer can be matched with a motor, diesel engine or 30-50 horsepower tractor. The main machine consists of a feeding mechanism, a cutting mechanism, a throwing mechanism, a transmission mechanism, a walking mechanism, a protective device and a frame. It has the characteristics of reasonable structure, convenient movement, automatic feeding, safety and reliability.

Straw fertilizer crusher components are as follows:

- Feeding mechanism: It is mainly composed of feeding table, upper and lower grooves, fixed blade and fixed knife support seat.

- Cut-off throwing mechanism: It is mainly composed of moving knife, cutter head, locking screw and so on.

- Transmission mechanism: It is mainly composed of V-belt, transmission shaft, gear, universal joint and so on.

- Walking mechanism: mainly composed of ground casters.

- Protective device: It consists of protective cover.

Technical parameters of different types of semi wet cow dung powder making machine

| Model | Power | Motor Speed | Spindle speed | Weights | Belts | Capacity |

| JL600 | 4-18.5kw | 1400r/min | 1400 r/m | 750/kg | B#2150×4 sets | 500-800kg |

| JL800 | 4-30kw | 1400r/min | 1400 r/m | 1150/kg | B#2600×4 sets | 1000-2000kg |

| JL1000 | 4-45kw | 1000r/min | 1000 r/m | 1950/kg | B#3300×4 sets | 3000-5000kg |

Semi-wet material grinder for cow powder making

Semi-wet material pulverizer is used for comminuting biologically fermented high-humidity materials such as bio-organic fermentation compost, urban domestic waste compost, grass peat carbon, rural straw waste, industrial organic waste, and livestock manure.

Semi wet cow dung powder making machine working performance

- Wide application and high reliability. The cow manure powder making machine is not designed with a sieve screen, and more than 100 kinds of materials can be crushed without blocking.

- Easy maintenance. The cow dung semi wet machine adopts two-way clearance adjustment technology. If the hammer piece is worn, the position of the moving hammer piece can continue to be used.

- Good crushing effect. The cow manure machine for powder making uses a two-stage rotor to smash the upper and lower stages. The material is first finely divided, then pulverized into fines, and then discharged.

- Save labor and easy operation. The cattle manure crushing machine uses high-tech technology, which can be easily operated by only one person. It is not only safe and reliable, but also easy to maintain.

- Semi-wet organic material fertilizer pulverizer is a professional pulverizing equipment for pulverizing high humidity and multi-fiber material. The semi-wet cow manure material crusher uses high-speed rotating blades to pulverize the fiber with good particle size, high efficiency and high energy. The semi-wet organic manure material grinder is mostly used in the production and processing of organic fertilizers. It has a good effect in crushing chicken manure, cow manure, sodium humic acid and other raw materials.

Semi-wet cow manure powder making machine working principle

- The semi-wet manure material crusher uses a two-stage rotor to smash the upper and lower stages. The material passes through the upper-stage rotor to pulverize into fine particles, and then is conveyed to the lower-stage rotor to continue to pulverize into fine powder. The best effect, the last discharge port is directly discharged.

- The semi-wet material fertilizer crusher is not designed with a sieve screen, and more than a hundred kinds of materials can be crushed without clogging. Even the materials just picked up from the water can be crushed, and will not be blocked by crushing the wet material, which will cause the motor to be burned and affect the production.

- The semi-wet organic material grinder adopts high-alloy wear-resistant hammer head, and the hammer piece is made of forging. It is particularly strong and wear-resistant, which is stronger and more wear-resistant than the ordinary hammer head, which increases the service life of the hammer piece.

- The semi-wet fertilizer crusher for cow manure making adopts two-way gap adjustment technology. If the hammer is worn, there is no need to repair it, and the position of the moving hammer can continue to be used. Adjusting the gap between the hammer head and the liner can control the material particle size of the material.

- The semi-wet cow dung fertilizer crusher adopts high-tech technology, which can be easily operated by only one person, which is not only safe and reliable, but also easy to maintain.

- The semi-wet manure grinder for powder production centralized lubrication system is filled with oil. Under normal work, the lubricant can be injected without stopping the machine.

Technical parameters of different types of semi wet cow dung powder making machine

| Model | Capacity (t/h) | Power (kw) | Particle Size(mesh) | Size(mm) |

| SXSF-40 | 1-1.5 | 22 | 50 | 1200×1350×900 |

| SXSF-40II | 1-1.5 | 22×2 | 80 | 1250×1600×1300 |

| SXSF-60 | 1.5-3 | 30 | 50 | 1300×1450×1300 |

| SXSF-60II | 1.5-3 | 30×2 | 80 | 1500×2150×1920 |

| SXSF-90 | 3-5 | 37 | 50 | 1800×1550×1700 |

| SXSF-120 | 5-8 | 75 | 50 | 2100×2600×2130 |

Cage Crusher for Cow Dung Powder Making

The cage grinder is a medium-sized horizontal cage grinder. The machine is designed according to the principle of impact crushing. The two sets of cage bars inside and outside rotate at high speed, and the materials are crushed by the impact of cage bars from the inside to the outside.

High crushing efficiency and smooth operation. The cage crusher has the advantages of simple structure, high crushing efficiency, good sealing performance, stable operation, easy cleaning and convenient maintenance.

Simple and compact, small footprint, easy maintenance and easy cleaning, it is the nemesis of monogranular, diammonium, urea and other hard granular materials.

Cage fertilizer crusher for cow dung fertilizer production

Before use, place the crusher flat on a certain place in the workshop. No equipment foundation is needed. It can be used after being connected to the power supply. The fineness of the crushing is controlled by the double roller spacing. The better the effect, the higher the output. The device can be designed to be mobile according to user requirements. It is very convenient to move the corresponding position when the user is using it, and to move it when not in use.

Technical Parameters of cage fertilizer grinder for cow powder production

| Model | Power(kw) | Capacity(t/h) | Feeding Port Size(mm) | Size(mm) |

| SXLSF-600 | 11×2 | 4-6 | 380×320 | 1500×1500×1500 |

| SXLSF-800 | 15×2 | 6-10 | 300×250 | 1500×1400×1500 |

Double shaft chain grinder for cow dung powder making

The double-shaft chain grinder is suitable for the crushing of masses in the production of compound fertilizers. It is also widely used in chemical, building materials, mining and other industries. During the crushing process, the high-strength concrete-resistant hard alloy chain plate with synchronous speed is used. The inlet and outlet design are reasonable, the crushed material is uniform, not easy to stick to the wall, and easy to clean. Crush all kinds of block fertilizers and other medium-hard block materials.

Double shaft chain grinder fertilizer crusher working performance

- Double rotor structure, each rotor shaft has its own transmission motor, the peripheral speed of the chain head.

- The machine is composed of a feed inlet, a body, a discharge outlet, a rotor (including a bearing), a transmission device and a shock absorber.

- In order to prevent friction between the sticky material and the steel plate of the body, a rubber plate is lined in the body, and quick-opening inspection doors are provided on both sides of the body.

Working principle of double shaft chain grinder

- The chain crusher is divided into two types of structure: vertical chain crusher and horizontal chain crusher. The vertical chain crusher is a single rotor, and the horizontal chain crusher is a double rotor. The main working part of the chain crusher is a rotor with a steel ring chain. One end of the ring chain is connected to the rotor. The other end of the ring chain is equipped with a ring head made of wear-resistant steel. The chain crusher is an impact crusher, which crushes the impact of the block by a high-speed rotating chain.

- Double rotor structure of horizontal chain crusher, each rotor shaft has its own drive motor, the peripheral speed of the chain head in the range of 28 ~ 78m/s.

- The horizontal chain crusher is composed of a feed inlet, a body, a discharge outlet, a rotor (including a bearing), a transmission device and a shock absorber.

- In order to prevent friction between the sticky material and the steel plate of the body, a rubber plate is lined in the body, and quick-opening inspection doors are provided on both sides of the body. The body and the transmission device are installed on a base made of steel, and a shock absorber is installed below the base. And connected to the foundation.

Technical Parameters of the double shaft chain grinder cow dung powder making machine

| Model | Center Distance mm | Capacity t/h | Materials Sizes mm | Powder sizes mm | Motor Model | Power(KW) | Size(L*W*H):mm | Weight(kg) |

| HFWS50 | 400 | 5~9 | <100 | ≤70%~90% | Y132M-4 | 7.5×2 | 1754×1292×1115 | 1425 |

| HFWS60 | 600 | 6~10 | <100 | Y160M-4 | 11×2 | 1800×1610×1430 | 2100 | |

| HFWS70 | 800 | 12~16 | <120 | Y160L-4 | 15×2 | 2200×1980×1510 | 3600 | |

| HFWS80 | 800 | 16~20 | <120 | Y180M-4 | 18.5×2 | 2320×2220×1730 | 4500 | |

| HFWS100 | 1000 | 20~25 | <120 | Y180L-4 | 30×2 | 2520×2200×1800 | 5400 |

Vertical grinder for cow dung powder making

Vertical cow dung fertilizer crusher is an optimized fine crushing equipment without screen bar, based on the absorption of fine crushing equipment at home and abroad. It can be widely used in one of the mainstream equipment of beneficiation equipment. It can be used for final crushing of various materials such as mixed materials, gypsum, coal gangue, slag, copper ore, etc. It is also one of the crushing equipment commonly used in the compound fertilizer industry. It is suitable for crushing of raw materials and regrinds, especially for moisture content. High material adaptability, not easy to block, smooth feeding.

Vertical fertilizer crusher for cow manure powder making working performance

- High crushing rate and energy saving.

- With fine crushing, coarse grinding function.

- Affected by the moisture content of the material, the moisture content can reach about 8%.

- The working noise is less than 75 decibels (db level), and there is less dust pollution.

- Suitable for crushing medium hard and extra hard materials.

Vertical type fertilizer crusher working principle

The vertical crusher structure consists of the lower frame, the casing, the upper and lower shaft seats, the main shaft, the hammer head, the hammer head bracket, the pulley, the motor frame, etc. The power drives the main shaft to rotate through a triangle belt, and the main shaft has two upper and lower bearing seats, and the bearing seat is installed at the upper and lower ends of the casing, the casing assembly is installed on the lower frame, the spindle is equipped with a hammer head and a hammer head bracket, and a hopper is installed at the upper part of the casing. In order to facilitate the installation and removal of the hammer head, a shutter is opened on the casing to facilitate Disassembly and repair.

Advantages of vertical grinder: The inner wall of the machine’s casing is lined with polypropylene plate, which alleviates the problems of sticking to the wall and difficult to clean. The chain cutter head is beaten with special steel, which can effectively improve production efficiency with reasonable structure, convenient operation, strong applicability, etc.

Technical parameters of fertilizer vertical crusher

| Model | Power(kw) | Capacity(t/h) | Feeding Port Size (mm) | Size(mm) |

| SXFLF-600 | 22 | 3-5 | 400×400 | 2100×1200×1700 |

| SXFLF-800 | 30 | 5-8 | 600×400 | 2600×1400×1900 |

| SXFLF-1000 | 37 | 8-15 | 650×450 | 2800×1600×1000 |