New Type Organic Fertilizer Granulator for Cow Dung Compost Pelleting

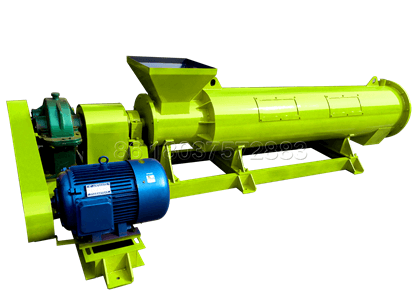

The newly developed organic fertilizer stirring granulator is a molding organic fertilizer granule making machine that can make organic materials into a specific pellet shape.

The wet stirring teeth granulating machine uses the high-speed rotating mechanical agitation force and the aerodynamic force generated by it to make the fine powder continuous mixing, granulation, spheroidization and densification in the machine, so as to achieve the purpose of cow dung compost granulation. This granulation method makes the granules have a high sphericity, beautiful granules, and saves energy.

New Type Cow Dung Compost Pellet Machine Working Principle

The principle of the new developed fertilizer granulator machine s simple and its granulation speed is fast. Using the high-speed rotating mechanical stirring force and the aerodynamic force generated by the leading design, the fine powder cow dung material can be continuously mixed in the granulator machine, granulating, spheroidizing, and compacting, so as to achieve high granulation rates.

Technical highlights of the newly developed cow dung powder pellet machine

- High granulation quality, this machine is especially suitable for granulation of light and fine organic manure powder materials. The finer the basic particles of the fine powder material, the higher the sphericity of the particles and the better the ball forming quality.

- No binder is needed, and the use of organic particles can grow inlaid with each other under a certain force, and no binder is needed during granulation.

- A wide range of organic materials applicable, livestock and poultry feces, urine, composting fertilizers, green fertilizers, sea fertilizers, cake fertilizers, peat, soil miscellaneous fertilizers, three wastes, and microbiotics.

- Wet granulation machine for organic manure pellet making uses high-speed rotating mechanical agitation force and the aerodynamic force generated by it, and the aerodynamic force generated by it, so that fine powder materials can be continuously mixed, granulated, spheroidized, and compacted in the machine to achieve a high quality granulation effect.

Newly Developed Organic Fertilizer Granulators Specifications

| Mddel | Iinstallation Angle | Production Capacity | Power | Moisture | Particle Size(Mesh) | Machine Size |

| SXJZ-600 | 2°-2.5° | 1-1.5t/h | 37kw | 20%-40% | 50 | 4100×1600×1150 |

| SXJZ-800 | 2°-2.5° | 1.5-2.5t/h | 55kw | 20%-40% | 50 | 4250×1850×1300 |

| SXJZ-1000 | 2°-2.5° | 2-4t/h | 75kw | 20%-40% | 50 | 4700×2350×1600 |

| SXJZ-1200 | 2°-2.5° | 4-6t/h | 90kw | 20%-40% | 50 | 4900×2550×1800 |

| SXJZ-1500 | 2°-2.5° | 6-8t/h | 110kw | 20%-40% | 50 | 5500×2800×2000 |

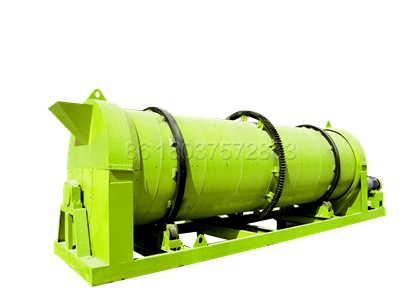

Rotatory Drum Fertilizer Organic Granulator with Stirring-teeth Machine for Cow Dung Compost Pellet Making

The newly developed dual-purpose granulator can turn cow dung powder materials into a specific shape. The cattle manure drum granulator is one of the key equipment in the compound and organic fertilizer industry. It is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound and organic fertilizers. The main working method is wet granulation of pellets. After a certain amount of water or steam, the basic fertilizer is fully chemically reacted after being humidified in the cylinder. Under certain liquid phase conditions, the rotation of the cylinder is used to make the material particles produce squeezing forces to reunite into balls. The barrel of the fertilizer granulator machine uses a special rubber plate lining or acid-resistant stainless-steel lining plate to achieve automatic scar removal and tumor removal, eliminating the traditional scraper device. This granulator machine has the characteristics of high ball strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life, convenient operation and maintenance, etc. The wet tooth-granulating granulator uses the high-speed rotating mechanical agitation force and the aerodynamic force generated by it to make the fine powder continuous mixing, granulation, spheroidization and densification in the machine, so as to achieve the purpose of granulation. The combination of these two granulation methods makes the pellets have a higher sphericity rate and more beautiful granules. At the same time, it saves energy.

Rotatory Drum Stirring Teeth Granulator Machine Working Performance

- The particle size distribution is centralized and easy to control. Compared with natural agglomeration and granulation devices (such as rotary disc granulators and drum granulators), the particle size distribution is concentrated.

- High organic content. The granules produced are spherical. Organic matter content can be as high as 100%, to achieve pure organic matter granulation.

- Granulation without edges and corners, powder rate is extremely low. Spherical particles have no acute angles after granulation, so the chalking rate is extremely low.

- Efficient. Easier to meet the requirements of mass production.

Utilizing high-speed rotation and mechanical agitation and the aerodynamic force generated thereby, the fine powdery material is continuously realized in the machine for mixing, granulation, spheroidization, and compaction, thereby achieving the purpose of granulation. The shape of the particles is spherical, the sphericity is ≥ 0.7, the particle size is generally between 0.3-3 mm, and the granulation rate is ≥ 90%. The size of the particle diameter can be appropriately adjusted by the mixing amount of the material moisture and the spindle speed. Generally, the lower the mixing amount. The higher the speed, the smaller the particles, and vice versa.

Technical Parameters of Rotatory Drum Fertilizer Granulator Machine with Stirring Teeth

| Mdele | Installation Angle | Capacity | Power | Size(mm) |

| SXZJZ-1660 | 2°-2.5° | 5-8t/h | 45+22kw | 7500×2200×2250 |

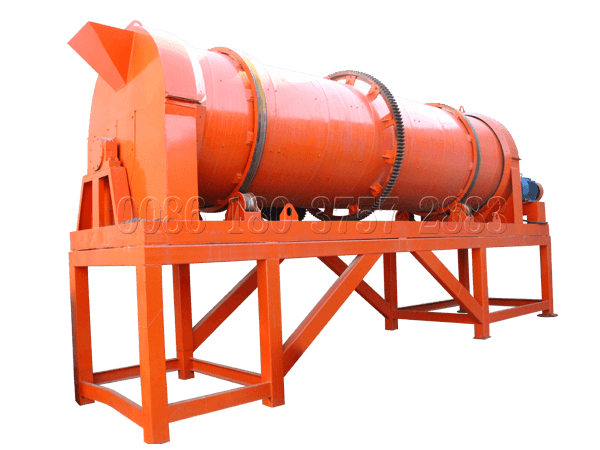

Drum Granulation Equipment for Cow Dung Pellet Fertilizer Making

This fertilizer machine for pellet manure compost making is a new generation of rotary drum granulator developed by our company‘s staff with many years of compound and organic fertilizer production experience. This machine has the characteristics of beautiful appearance, simple operation, low energy consumption, long life, uniform drying, convenient maintenance, etc. It is a relatively advanced granulation equipment in China. This product is suitable for cold, hot granulation and high, medium and low concentration compounding. For large-scale production of mixed fertilizer, the product has now spread throughout the country.

Technical innovation and improved structure. The barrel adopts a special rubber plate lining or acid-resistant stainless-steel lining plate, which realizes automatic scar removal and tumor removal, and eliminates the traditional scraper device.

Technical Highlights of drum granulators

- High abrasion resistance, easy maintenance, high ball strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life, convenient operation and maintenance, etc.

- Reasonable layout, low power, no waste discharge, stable operation, convenient maintenance, reasonable process layout, and low production cost.

- High ball forming rate, high drying efficiency, ball forming rate up to 70%, a small amount of returned material, small size of the returned material, re-granulation; steam heating to increase the temperature.

How does the cow manure drum granulator work?

The working principle of this series of manure granulators is: Driven by the main motor, belt and belt wheels running, power can be transmitted by the main bear, the main body of the drum granulator can work for organic and compound materials granulating. Raw materials can be added through the materials charging port and out from the discharging port. It can be used for large capacity of organic granules fertilizer production with continuously granulation design technology.

Cow Manure Drum Granulator Machine Technical Parameters

| Model | Power(kw) | Inner Dia. (mm) | Length (mm) | Angle(。) | Speed(r/min) | Capacity(t/h) |

| SXZ1240 | 5.5 | 1200 | 4000 | 2-5 | 17 | 1-3 |

| SXZ1560 | 11 | 1500 | 6000 | 2-5 | 11.5 | 3-5 |

| SXZ1870 | 15 | 1800 | 7000 | 2-5 | 11.5 | 5-8 |

| SXZ2080 | 18.5 | 2000 | 8000 | 2-5 | 11 | 8-15 |

| SXZ3210 | 37 | 3200 | 10000 | 2-5 | 9.5 | 15-30 |

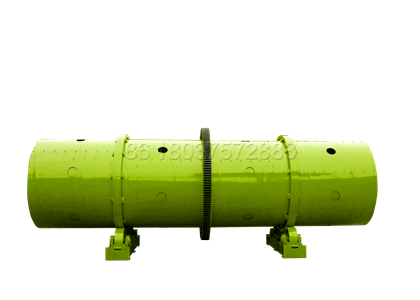

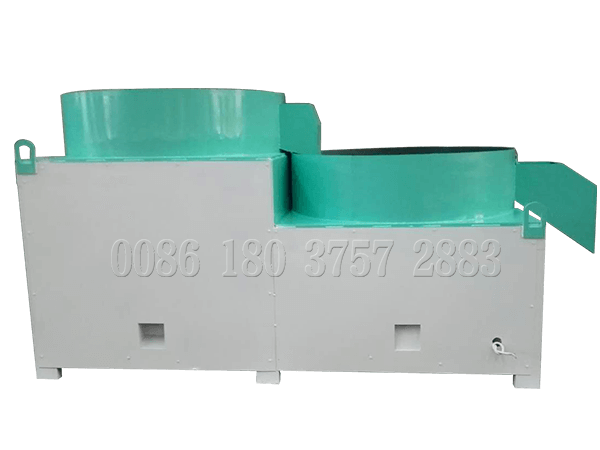

Cow Dung Pellet Fertilizer Polishing Machine

Organic manure fertilizers and compound fertilizers have different shapes when they first form fertilizer granules, and the sizes of the granules are different. In order to make the fertilizer granules look beautiful, our fertilizer machine company has developed organic fertilizer rounding machines, compound fertilizer rounding machines and other rounding machines series.

The organic fertilizer polishing machine is a rounding device configured on the basis of organic fertilizer and compound fertilizer granulators, which makes cylindrical particles roll into balls at one time, no return, high ball forming rate, good strength, beautiful and practical. Organic fertilizer (bio) ideal equipment for making spherical particles.

Why should customers equip a fertilizer granulator polishing machine for your plants?

- The output is high and the machine is flexible in arrangement. Single or several granulators can be used at the same time, which solves the disadvantages of the complicated process and large equipment investment brought by the past that the granulator must be equipped with a rounding machine.

- The finished product has the same granularity and high yield. The machine consists of two or more throwing cylinders arranged in sequence. The material is discharged from the discharge port after multiple rounds of rounding. The finished product has the same particle size, large density, roundness and smoothness, and high yield.

- Simple structure, easy operation and maintenance. The cylindrical particles can be rolled into balls at one time, the appearance is beautiful, the structure is simple, safe and reliable, and the operation and maintenance are convenient. It can be used according to the instructions.

- The ability to adapt to the environment is strong, the cost is low, and the benefit is high. Strong anti-overload ability, able to adapt to work in various environments. Low power consumption and production costs.

Where can you use the organic granular fertilizer polishing machine?

This machine consists of two or more throwing cylinders arranged in sequence. The material is discharged from the discharge port after multiple centrifugal throwing rounds. The finished product has the same particle size, large density, roundness and smoothness, and the finished product rate is as high as 95%.

The organic fertilizer polishing machine uses organic manure such as chicken manure as the main raw material, compound fertilizer, compound fertilizer to round the particles; grass ash, lignite, organic fertilizer sludge, straw, etc. as raw materials, round the particles; rounds of cake fertilizer particles with bean cake as the main raw material; rounds of various fertilizers and feed particles.

Cow Manure Fertilizer Granules Polishing Machine Parameters

| Model | Capacity | Power | Dia. | Size(mm) |

| SXPY-800 | 1-2t/h | 5.5kw×2 | 800mm | 2800×920×1290 |

| SXPY-1000 | 2-3t/h | 5.5kw×2 | 1000mm | 3100×1020×1390 |

| SXPY-1200 | 3-5t/h | 7.5kw×2 | 1200mm | 3400×1120×1490 |

| SXPY-1500 | 5-8t/h | 11kw×2 | 1500mm | 3200×1550×1600 |

Flat Die Granulator for Cow Manure Compost Making

One of the main (biological) organic fertilizer production equipment currently produced is based on the domestic and foreign pellet machines of our factory. Based on many years of production experience, we have repeatedly researched, improved, and carefully manufactured fertilizer machinery. The machine has excellent technology and simple operation.

What’s the working performance of the flat die granulating machine?

- This machine is mainly used for pellet processing in (bio) organic fertilizer and aquaculture processing industries;

- The surface of the granulated material processed by this machine is smooth, the hardness is moderate, the temperature rise is low during the processing, and it can better maintain the nutritional components inside the raw material;

- The particle composition is uniform and the shape is neat. The diameter of the particle diameter can be divided into: Φ2, Φ2.5, Φ3.5, Φ4, Φ5, Φ6, Φ7, Φ8 and so on. Users can choose according to production needs when ordering;

- Due to the low moisture content of the particles, it is easy to store and can remain in the original state for a long time in the water, which greatly improves the utilization rate of materials.

Technical design highlights of the flat die granulator machine

- The surface of the granulated material processed by this machine is smooth, moderate in hardness, and the temperature rise is low during processing, and it can better maintain the nutritional components inside the raw material.

- The granules produced by this machine have low water content and are easy to store. They can remain in the original state for a long time in water, which greatly improves the utilization rate of materials.

- The machine adopts a central pressure regulating structure to adapt to different materials and ensure the pressing effect. Compression molding of wood chips and corn stalks requires a lot of pressure.

- This type of press roller uses inclined wheels. And the two ends are consistent with the linear speed of the inner and outer rings of the die plate, and no misaligned friction between the wheel and the die occurs, which reduces the resistance and the kinetic energy.

7 quick ways to operate the flat die granulator machine for cow dung processing

- Start up after adding hyperbolic gear oil to the gearbox;

- Install the granulator smoothly, adjust whether the belt is tight and whether the steering is normal. Imagine whether the screws of each part are loose.

- Loosen the gap adjustment screw on the roller shaft seat, so that the machine can be put into use after it is started normally without load.

- For the first use of the new machine, take 10 kg of grass powder (or sawdust), 2 kg of fine sand, and add (about 1.5 kg) vegetable oil or waste engine oil (Note: it can also be replaced by abrasives with larger oil content). The gap between the screw and the roller and the template is 0.1-0.3 mm. Make the two rollers rotate at the same speed.

- Gradually add the oily material. The extruded particles are repeatedly squeezed to make the film holes lubricate smoothly, and then slowly add the mixture to be processed. Processing, if you feel that the film hole resistance is large, the output is low, or the material is not discharged, you can repeatedly grind the film plate according to the above method to make the film hole lubricate smoothly before processing;

- If there are more fine fibers during material processing, about 5% of water should be added. If there are more fine fibers in the mixture, the amount of water added can be reduced as appropriate, and this water will be exerted during the extrusion process;

- Loosen the gap adjustment screw after processing. Keep the rollers in a free state. After the machine is stopped, remove the dirt on the upper and lower bins, especially the remaining material under the disc to avoid damaging the bearings.

Flat Die Cow Manure Pellet Machine Technical Specifications

| Model | Capacity | Granulating Rates (%) | Temperature (℃) | Power (KW) |

| Kp-150c | 0.08-0.1 | >95 | <30 | 5.5 |

| Kp-250c | 0.5-0.7 | >95 | <30 | 15 |

| 5Kp-300c | 0.8-1.0 | >95 | <30 | 22 |

| Kp-350c | 1.1-1.8 | >95 | <30 | 30 |

| Kp-400c | 1.5-2.5 | >95 | <30 | 37 |

Disc granulator for cow dung compost pellet making

The disc granulator is widely used in the processing of bio-organic fertilizer spherical particles, such as pulverized coal, cement, clinker, chemical fertilizer and other materials.

The disc granulator (also known as a ball disc) is a volumetric metering feeding device, which can feed the material evenly and continuously to the next process, and can withstand a large pressure. As a fine-grained material feeding equipment, it is suitable for conveying various non-sticky materials in powder, material or small pieces, such as pulverized coal, cement, clinker, limestone, shale, coal gangue, clay, etc. Or small pieces.

The disc angle of the disc granulator adopts the overall arc structure, and the granulation rate can reach more than 93%. The granulating disc is provided with three discharge openings, which is convenient for intermittent production operations, which greatly reduces labor intensity and improves labor efficiency. The reducer and motor are driven by a flexible belt, which starts smoothly, reduces the impact force and increases the service life of the equipment. The bottom of the granulating disk is strengthened with multiple radiant steel plates, which is durable and never deformed. Heavy, thick, sturdy base design, no anchor bolts required, stable operation. The main gear of the granulator adopts high-frequency quenching, and the service life is doubled. The granulated disk is lined with high-strength glass fiber reinforced plastic for corrosion resistance and durability. This side has the advantages of uniform granulation, high granulation rate, stable operation, rugged and durable equipment, and long service life. It is an ideal equipment for users to choose.

Top 5 reasons for organic fertilizer business customers buying this machine

- Efficient. The disc angle of the disc granulator adopts the overall arc structure, and the granulation rate can reach more than 93%.

- Long service life, new dredging design, edge cleaning and bottom cleaning by unpowered combination scraper, corner cleaning blade and corner cleaning blade, combined with the unique treatment technology of the disc body, the effect of dredging and ball formation is good.

- The bottom of the granulating disk is strengthened with multiple radiant steel plates, which is durable and never deformed. Thickened and aggravated. The main gear of the granulator adopts high frequency quenching, and the service life is doubled.

- The granulator disk is lined with high-strength glass fiber reinforced plastic, which is corrosion-resistant and durable. It has the characteristics of high granulation rate, stable operation, rugged and durable equipment, and long service life.

How does the pan granulator produce cow dung pellets?

The raw meal powder is evenly mixed by pre-adding water, and is input into the pan. As the pan rotates, the material gradually rolls into a spherical shape within the pan body, reaches a predetermined diameter, is discharged out of the pan, and is then transported to the next process.

Pan Granulator Cattle Manure Pellet Machine Specifications

| Model | Pan Dia.(mm) | Heights(mm) | Speed(min) | Power(kw) | Capacity(T/h) | Reducer Model | Size(mm) |

| SXYZ-500 | 500 | 200 | 32 | 0.55 | 0.02-0.05 | BWY0-43-0.55KW | 650×600×800 |

| SXYZ-600 | 600 | 280 | 33.5 | 0.75 | 0.05-0.1 | BWY0-43-0.55KW | 800×700×950 |

| SXYZ-800 | 800 | 200 | 21 | 1.5 | 0.1-0.2 | XWD4-71-1.5KW | 900×1000×1100 |

| SXYZ-1000 | 1000 | 250 | 21 | 1.5 | 0.2-0.3 | XWD4-71-1.5KW | 1200×950×1300 |

| SXYZ-1200 | 1200 | 250 | 21 | 1.5 | 0.3-0.5 | XWD4-71-1.5KW | 1200×1470×1700 |

| SXYZ-1500 | 1500 | 300 | 21 | 3 | 0.5-0.8 | XWD5-71-3KW | 1760×1500×1950 |

| SXYZ-1800 | 1800 | 300 | 21 | 3 | 0.8-1.2 | XWD5-71-3KW | 2060×1700×2130 |

| SXYZ-2000 | 2000 | 350 | 21 | 4 | 1.2-1.5 | XWD5-71-4KW | 2260×1650×2250 |

| SXYZ-2500 | 2500 | 450 | 14 | 7.5 | 1.5-2.0 | ZQ350 | 2900×2000×2750 |

| SXYZ-2800 | 2800 | 450 | 14 | 11 | 2-3 | ZQ350 | 3200×2200×3000 |

| SXYZ-3000 | 3000 | 450 | 14 | 11 | 2-4 | ZQ350 | 3400×2400×3100 |

| SXYZ-3600 | 3600 | 450 | 13 | 18.5 | 4-6 | ZQ400 | 4100×2900×3800 |