Compost Turner Equipment Manufacturing Machinery will provide you the latest news, cases, and solutions for compost making plants. Right here you will get most recent knowledge about our factory new designed compost facilities, project solutio cases to our customsers, compost production methodsm, maintenance and application operations of our machines, etc.

Top 5 compost machines for organic fertilizer production in 2025

Compost Mixer, Shredder, Crusher & Windrow Turner Solutions for Efficient Organic Fertilizer Production (2025 Guide)

If you’re searching for reliable compost processing machines—such as compost mixers, compost shredders, cow dung mixing machines, windrow turners, and composting tanks—this complete guide will help you understand the right machine for your fertilizer project, especially for users working with cow dung, leonardite (leonardit), and other organic raw materials.

1. Compost Mixer — Improve Uniformity in Every Batch

A compost mixer is essential for blending raw materials such as cow dung, leonardite, chicken manure, straw, food waste, and various additives. High uniformity mixing ensures stable compost fermentation and high-quality final fertilizer.

⭐ Features

- Horizontal or vertical design

- Adjustable mixing speed

- High uniformity rate (≥95%)

- Suitable for organic fertilizer and bio-organic fertilizer plants

👉 Best for

- Daily compost plants

- Fertilizer factories

- Farms composting cow dung

2. Compost Shredder Machine — Reduce Size & Speed Up Fermentation

A compost shredder (also known as a compost crusher) is used to break down bulk organic materials such as manure clumps, straw, sawdust, tree branches, and dried compost lumps.

⭐ Advantages

- High moisture tolerance

- Adjustable particle size

- 5–15 tons/hour capacity

- Reduces fermentation time by 30–50%

👉 Ideal for

- Pre-fermentation processing

- Fine compost particle preparation

- Plants using cow dung + carbon sources (straw, sawdust)

3. Cow Dung Mixing Machine — Specially Designed for Manure Processing

Cow dung requires uniform mixing with auxiliary materials such as straw, rice husk, or leonardite to achieve the correct C/N ratio (25–30:1) before composting.

⭐ Benefits

- Handles high-moisture cow manure

- Prevents clogging

- Ensures fast temperature rise

- Improves final compost quality

4. Compost Tank / Composting Tank — Automatic Aerobic Fermentation System

A composting tank is a fully enclosed, 7-15 days rapid fermentation system.

The tank uses automatic aeration, mixing, deodorization, and temperature control to produce pathogen-free compost with minimal land and labor.

⭐ Features

- Stainless steel or carbon steel construction

- 5–150 m³ capacities

- Odor-free sealed structure

- Automatic moisture discharge

- Suitable for urban and commercial applications

👉 Best for

- Food waste treatment

- Cow dung & chicken manure composting

- Small land footprint projects

5. Windrow Turner — The Most Popular Compost Production Method

Windrow composting remains the most cost-effective method for large-scale organic fertilizer production.

⭐ Why Choose a Windrow Turner?

- Turns long compost piles (windrows)

- Provides oxygen evenly

- Reduces moisture

- Accelerates fermentation

- Suitable for municipal solid waste & manure

Types

6. Composting Machine Options — Complete Plant Solutions

Depending on your raw materials and production capacity, compostturnermachine.com provides full solutions:

🔧 Machines Available

- Compost mixers

- Compost shredders & crushers

- Cow dung processors

- Windrow turners

- In-vessel composting tanks

- Screening, bagging & granulation equipment

♻ Suitable Raw Materials

- Cow dung

- Chicken manure

- Leonardite

- Green waste

- Industrial organic residues

7. Recommended Compost Production Line for leonardite (leonardit)

Since your submitted material mentions leonardit, here is a tailor-made solution:

Leonardite Organic Fertilizer Production Flow

- Crushing / Shredding

- Compost Mixing with manure or additives

- Aerobic Composting (Windrow or Compost Tank)

- Screening & Moisture Adjustment

- (Optional) Granulation — Rotary Drum Granulator / Disc Granulator

- Drying & Cooling

- Packing

Leonardite is rich in humic acid, ideal for high-value soil improvement fertilizers.

8. Contact Information for Business Inquiries

(Optimized for local SEO trust signals)

Contact Person: Jhon

Company: YUSHUNXIN

Email: sales@compostturnermachine.com

Phone/WhatsApp: +86 182 0399 3035.

9. Get a Free Compost Project Proposal Today

If you’re planning to build an organic fertilizer plant, leonardite processing line, or cow dung composting system, we can design a full solution for you:

✔ Equipment selection

✔ Layout design

✔ Investment & cost analysis

✔ 1–20 tons/hour production plan

✔ Price estimate (FOB / CIF)

📨 Request a quotation now (WhatsApp available):+86 182 0399 3035

👉 Contact Us at CompostTurnerMachine.com

Compost Turner Groove Type Image Collections

Compost Turner Trench Type, also name as groove or rail type compost turning equipment. It usually works in the trench or groove for compost fertilizer production applications. In organic waste recycling industry, the groove composting eqauiment can be widely used in livestock manure, sugar mill waste composting process. For easy, effcient and economical compost manufacturing, this type of aerobatic fermentation equipment is the top chioces for organic fertilizer production plants, animal manure recycling plants. How do we design and manufacturer the groove type compost machine? What is the structure of the machine? How about its spare parts and componenets? In the following, we will share you some latest images of the compost turner trench type. Detailed info is as following.

What is a groove type compost turner machine?

The Main Componenets of the Groove Type Compost Turning Equipment

How do we tailor compost turner forour customer?

How to install the groove type compost turner machine?

Phosphatic Granule Fertilizer Production Line in Uzbekistan

Phosphatic Granule Fertilizer Production Line Onsite Installation in Uzbekistan

This is a 1 to 2 ton per hour throughput granulation line for phosphatic fertilizer production installation video from our factory. Our installation engineer has been to our Uzbekistan client’s fertilizer plant for two weeks, since the mid of Dec. 2019. From site budilding to the fertilizer equipment installation, our engineer has provided his full proffssional support to our UZ customer.

What main fertilizer equipment included in the Phosphatic fertilizer production line?

The 1 to 2 ton fertilizer production line is mainly designed for granules phosphatic fertilizer producing. Our factory has manufactured and configured the following equipment for our customer.

Main Phosphatic fertilizer production Equipment: Grinding, Granulation and Coating

Chain Type Fertilizer Crusher: for Phosphatic fertilizer lumps grinding. It adopts high-strength concrete-resistant hard alloy chain plate with synchronous speed. This technical design promotes the working performance of the chain fertilizer crushing equipment. With optimized feed in and out port, raw materials can be crushed smoothly and efficiently. Customers can clear this type of chain grinder easily.

Rotary Drum Granulator: Key granulation equipment for compound fertilizer production in a large scale. This type of fertilizer granulation equipment can be applied to hot and cold fertilizer granulation. The rotary drum phosphatic granulation machine adopts wet granulation technology, achieving large scale fertilizer production.

Organic Compound Fertilizer Production Line in Malaysia

Factory Customzied Compound Fertilizer Equipment Products Shipping to Our Malaysia Client

On January 4th, 2020, the dactory has finished all the manufacturing and packing work for our Malaysia’s clinet’s compound fertilzier manufacturing plant. It is a 1 ton granular fertilizer npk and organic fertilzier production line, which manily includes, 1 ton double roller granulator, new type organic rotary durm granulator, fertilizer polishing machine, fertilizer belt conveyor, rotary screener, etc.

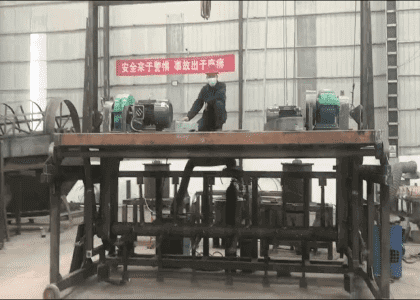

Five-warehouse automatic load-bearing batching installation site

Five-warehouse automatic load-bearing batching installation site for an organic fertilizer production line with an annual output of 10,000 tons

4 meters Width Chain Plate Compost Turner Onsite Installation

4 meters Width Chain Plate Compost Turner Onsite Installation Video

Chain plate composting machine is suitable for trench aerobic composting of organic solid waste such as livestock manure, sludge garbage, straw and so on. The traveling system of the machine adopts the advantages of variable frequency speed regulation, good adaptability to different materials, stable operation, high stack turning efficiency, and deep groove operation, which can effectively shorten the fermentation cycle, improve production efficiency and product quality. Adopting variable frequency speed control speed walking system, can well adapt to changes in workload. The walking speed can be flexibly adjusted according to the resistance of the material, so that the equipment has stronger adaptability and flexibility. Optional moving vehicles can be used to realize the operation of multi-tank equipment. When the capacity of the equipment allows, simply adding a fermentation tank can expand the production scale and increase the value of equipment.

Disc pan compost pelletizer in inner mongolia

Shunxin 2.5m disc pan compost pelletizer is being loaded to our Inner Mongolia cutstomers

From manurfacturing to delivering the products, it only takes less than one month, the company’s team tailored a 2.5m disc pan granualtor for our Inner Mongolia’s clients large scale compost farm plants. Tonday, on August 7th, 2019, we are ready to send our quality compost pellet making machines to our client’s farm.

More information about pan compost pellet making machine

Pan compost pellet making machine is also named as disc granulator manufactured from Shunxin Compost Tunrer Machine Making Facotry. It is a quality and low cost compost pellet machine for compost farm plant owners. It has three charging ports, whis is specially designed for compost materials discontinuous production. This design technology compost making plant owners’ workers labor intensity to a large degree. In the reducer and motor design, the engineer uses flexible belt drive to let the pan pelletizer work smoothly. By this structural design, the disc granulator for pellet compost making can work for a longer timer than traditional pan granulation making machines. In the compost pelletizer base design, we use a plurality of radiant steel plates to strengthen the pan granulator bottom base. Equipped with this machine you can make pellet composts freely. Customers want to make compound fertilizers, such as npk, dap, sop, can also use this type of pelletizer.

What technical specifications of disc pan compost pellet production machines can we customize for you?

In Compost Turner Making Machinery, the company can make different types of disc pan granulation with different specifications. Customers have idfferent requirements in the pellet sizes, the engineer can tailor you the disc pelletzier granulating 2mm(minium), and 8mm at most. If your compost pelleting requirements are in capacities, the company can manufacture different types of pan granulators with various kinds of capacities. From 0.5t/h in the minium to 6t/h in the maximum, the factory can produce for you. In the configurations, the company can equip your factory with different components specifications, such as reducers, motors, dic diameters, etc.

Main technical parameters of disc pan compost pellet production equipment

- Weight: 0.33t-5t

- Capacity: 0.5-6t/h

- Edge Height: 200-450mm

- Rotary Speed: 32-13r/min

- Diameter of Disc: 500-3600mm

- Dim.: 650*600*800mm-4100*2900*3800

- Inner lining: #304 Stainless steel

How useful was this post?

Click on a star to rate it!

Average rating 1 / 5. Vote count: 1

No votes so far! Be the first to rate this post.