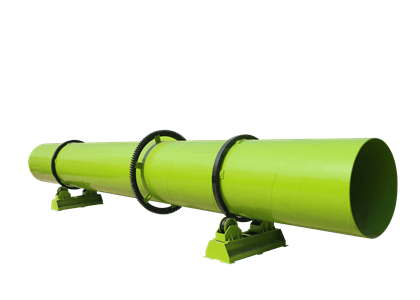

Organic Fertilizer Drying Machine: Lees dryer for sale

Beer lees is the solid material remaining after brewing will filter or press filter the malt, rice and hops through saccharification and gelatinization processes. Its main constituents are wheat husk, wheat germ, rice germ and endosperm. These constituents contain a large number of undecomposed and difficult to decompose high-molecular nutrients such as crude protein, crude fiber and crude fat. It has been processed into One of the sources of feed protein ingredients.

Residues of white spirits are distilled from the grains of alcohol or alcoholic beverages and used as livestock feed. The residues of brewing are removed by coarse filtration to remove the solid residues and fine particles remaining after solid grains.

Lees drying machine working performance

- High degree of mechanization of drying, large production capacity and continuous operation.

- The structure is excellent and simple, the material runs smoothly through the resistance of the cylinder, and the operation is convenient.

- Fewer failures, lower maintenance costs, and lower power consumption.

- The uniformity of product drying.

- The product has no odor after drying.

Organic fertilizer drier for lees drying working principle

The largest amount of by-products in breweries is wet beer lees, but wet lees are susceptible to deterioration, so it is easy to pollute the environment during transportation and storage. In recent years, many breweries have begun to further process beer by-products, which can reduce environmental pollution can also increase economic benefits. The beer lees dryer can quickly dehydrate and dry the wet beer lees with a moisture content of about 85% to dry products with a moisture content of about 10%. At present, this set of equipment has been used in China. A number of beer companies and feed processing companies have been put into use and have created considerable economic benefits. The beer lees dryer is mainly composed of a heating source, a feeding machine, a feeder, a rotary drum, a discharge machine, an induced draft fan, an unloader and a power distribution cabinet. After the dehydrated wet beer lees enters the dryer, Under the flip of the uniformly distributed copying plate in the drum, it is evenly dispersed in the dryer to fully contact the hot air, which accelerates the heat and mass transfer during drying. During the drying process, under the action of the inclined plate and the heat medium, the beer grains are discharged to the star-shaped discharge valve of the other section of the dryer to discharge the dried products.

Technical Parameters of lees drying machine

| Model (mm) | Inclination (%) | Speed (r/min) | Temperature (℃) | Power (kw) | Capacity (t/h) | Weight (t) |

| Ф600×6000 | 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

| Ф800×8000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 |

| Ф800×10000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

| Ф1000×10000 | 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

| Ф1200×10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

| Ф1200×12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

| Ф1500×12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

| Ф1800×12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

| Ф2200×12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

| Ф2200×18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

| Ф2200×20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

| Ф2400×20000 | 3-5 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

| Ф3000×20000 | 3-5 | 1.5-5 | ≤800 | 55 | 25-35 | 78 |

| Ф3000×25000 | 3-5 | 1.5-5 | ≤800 | 75 | 32-40 | 104.9 |

Rotatry drum organic fertilizer dryer for sale in Shunxin Fertilizer Macchine Factory

Organic fertilizer rotatry drum dryer is one of the traditional drying equipments. It has reliable operation, flexible operation, strong adaptability and large processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar, etc field, diameter: Φ1000-Φ4000, length depends on drying requirements. In the center of the tumble dryer, it is possible to avoid adding a scattering mechanism, and the wet materials entering the drying cylinder are repeatedly picked up and dropped by the copyboard on the drum wall, and are broken into fine particles by the scattering device during the falling process. The specific area is greatly increased, and it is fully in contact with hot air and dried.

Performance characteristics of rotatry drum machine for organic materials drying

- The distribution and angle design of the lifting plate of the drum dryer is reasonable and the performance is reliable, so the heat energy utilization rate is high and the drying is uniform.

- The tumble dryer equipment adopts a self-aligning tug structure, and the cooperation between the tug and the rolling ring is good, which greatly reduces the wear and power consumption.

- The specially designed blocking wheel structure in this equipment greatly reduces the horizontal thrust caused by the equipment’s tilting work. Strong anti-overload capability, stable cylinder operation and high reliability.

- The dryer has the characteristics of high temperature resistance, and can use high temperature hot air to quickly dry the material. Strong scalability, the design takes into account the production margin.

- The tumble dryer has a large processing capacity, low fuel consumption and low drying costs.

How does the rotatry drum fertilizer drier machine work?

The tumble dryer is mainly composed of a rotating body, a lifting plate, a transmission device, a support device and a seal ring. The dry wet material is sent to the hopper by the belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The slope of the feeding pipe should be greater than the natural inclination of the material so that the material can flow into the dryer smoothly. The dryer cylinder is a rotating cylinder slightly inclined from the horizontal line. The material is added from the higher end, the heat carrier enters from the lower end, and comes into countercurrent contact with the material. There is also the heat carrier and the material flowing into the cylinder together. As the cylinder rotates, the material moves to the lower end under the effect of gravity. During the forward movement of the wet material in the cylinder, the heat is directly or indirectly obtained by the heating medium, so that the wet material is dried, and then sent out by a belt conveyor or a screw conveyor at the discharge end.

Technical Parameters of organic rotatry drum fertilizer drying machine

| Model (mm) | Inclination (%) | Speed (r/min) | Temperature (℃) | Power (kw) | Capacity (t/h) | Weight (t) |

| Ф600×6000 | 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

| Ф800×8000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 |

| Ф800×10000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

| Ф1000×10000 | 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

| Ф1200×10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

| Ф1200×12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

| Ф1500×12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

| Ф1800×12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

| Ф2200×12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

| Ф2200×18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

| Ф2200×20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

| Ф2400×20000 | 3-5 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

| Ф3000×20000 | 3-5 | 1.5-5 | ≤800 | 55 | 25-35 | 78 |

| Ф3000×25000 | 3-5 | 1.5-5 | ≤800 | 75 | 32-40 | 104.9 |