Organic fertilizer production trends in Malaysia

About 43% of the cumulative GDP contribution from agriculture, rubber, forestry, and fisheries comes from palm oil, about 14% from fruits and vegetables, 13% from livestock farming, and 12% from fisheries. These industrial fields produce quantities of organic materials, like farm wastes, palm wastes, rubber wastes, fish muds, available to make organic fertilizer. Turning these organic materials into fertilizer is a sustainable way to develop the country’ economy.

Rich organic waste resources bring great opportunities to Malaysia’s organic fertilizer production business. ShunXin Fertilizer Equipment Manufacturing Factory is dedicated itself to providing professional solutions and quality organic fertilizer production lines and associated equipment, such as, compost turners, granulators, mixers, screeners, driers for customers all around the world. The following is one of a recent success cases of our fertilizer machine company provide our machines and services for one of our organic fertilizer making company client in Malaysia.

Malaysia organic fertilizer company customer basic demands:

This customer opens an organic fertilizer company in Malaysia, and he wants to use saw dusk, manure, and powder clay as based materials to make fertilizers. The processing capacities of his company to the raw materials are 20 metric tons per day. He needs our solutions to his company to make organic manure. From the basic information of his inquiry in processing capacity, organic raw materials to make organic fertilizer, our company’s professional team provide our best solutions for his in organic equipment selection, production line configuration, after sale services, including machine operation training, installation, maintaining, etc. Detailed information is as follow.

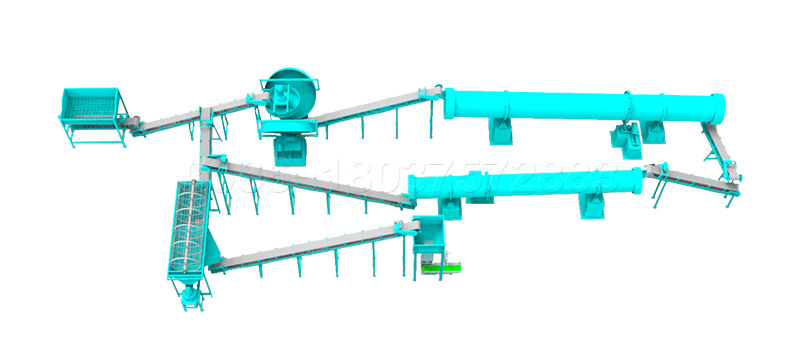

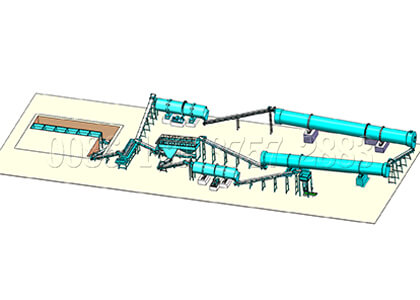

Organic fertilizer machines configured in the organic fertilizer production line

Based on his companies processing capacities our engineer designs an organic fertilizer production line with 1ton production capacity per hour. Since his different raw materials are all in powder shapes, the engineer recommends fertilizer mixers with capacity of 1 ton per hour one unit, our newly designed vibration screener one set, 1.5 ton silo atau bin hopper, and 20 ton capacity per day belt conveyor and 1 ton per hour pan granulator. Why configures theses machines for his organic fertilizer plants, please take a look the following brief introductions to the machines’ functions.

.jpg)

Quick overview to the organic fertilizer production process

From raw materials to finished organic fertilizers (round pellet shapes), it mainly needs the following processes:

First: raw material pretreatment (dewatering, mixing, crushing) based on materials status.

Second: Materials Composting (compost turners, fermentation tanks can be used in this process for speeding up this progress)

Third: Composted materials granulating or pelleting(different types of granulators are available based on customers production capacity, budget, working performance, and raw materials.)

The above are main processes to turn organic materials into granular fertilizers. In the organic production process, some associated machines are also quite important, such as screeners for efficient and quality fertilizer production, belt conveyors for fertilizer production materials conveying, bin hoppers for materials stocking, etc.

Brief introductions to the configured machines function in the Malaysia 1 ton per hour organic fertilizer production line

- 0.5 to 1ton Fertilizer Mixer one unit: for manure, sawdust, powder clay evenly mixing.

- 1 ton per hour Pan granulator: for powdery mixed organic materials granulating.

- Single layer Vibrating screener: to screen unqualified materials out for re-granulating.

- 1.5ton capacity Silo atau bin hopper: to promote the working performance and fertilizer quality of the fertilizer, the 1.5ton capacity hopper is mainly used for stocking mixed organic matters for fertilizer manufacturing.

- 20t/day belt conveyor: to ensure the whole organic fertilizer production process goes on well, the belt conveyor is necessary.

Top questions our Malaysia customers asked in his organic fertilizer production line machines selection and purchasing

Q:What is the warranty of the production machines you manufactured? And moto after sale?

A:Warranty:12 months after received machines; all of our machines are manufactured based on strictly national and international standard in the industrial field, production quality is guarantee, and the structure of our machine is smart and available to easy maintenance, and our service is also available in 24 hours both online and offline.

Q:what can you offer me, we are organic fertilizer company, base used mixer saw dusk, manure, powder clay?

A: As a professional organic and compound fertilizer machine manufacturer, the factory can tailor quality organic fertilizer machines to our customers all around the world.

Q: how much the organic fertilizer production line machine? Perday our prouduct is 20mt.

A: as for the organic fertilizer producing line machine cost and price will be based on customers’ demands on its production capacity, budgets, machine configurations, etc. One thing for sure is we are the fertilizer machine manufacturer can provide our best factory price for customers. Besides, to support customers dedicated themselves in sustainable development in fertilizer production business, our company also provide different discounts and price preferences according to government policies.

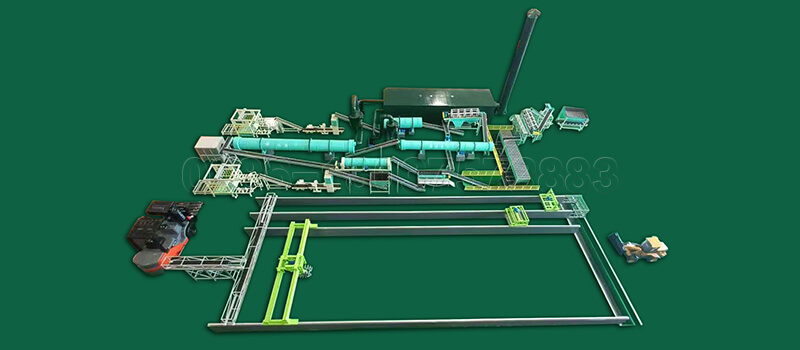

Q: any one will come to set the machine?

A: yes, all our fertilizer machines to make organic fertilizer are designed and manufactured with simple and smart struct for easy operation. As for the training and maintenance service, we will assign our Engineer to customers site to direct installation and stuff training, if customer needed.

Q: the machine stuck, stop doing to electricity organic dusk or machine failure?

A: it’s structure is very simple, easy to operate and maintain, while our engineer at your site, he will train your people how to operate and maintain the machines, and even after our engineer left, your people meet some problem cannot be. And when shipping the organic machines to customers fertilizer plants, the company will send some easy worn parts for free. Customers can change the worn parts in time without production delay. To prolong the service time of the machines, the company will send maintenance instructions to our customers also.

Q: Do you sell machines to Malaysia, and have you ever exported to Malaysia and other countries?

A: we are international fertilizer equipment manufacturing company, integrated with machine manufacturing, wholesaling and exporting all around the world. In the meantime, we have provided our machines, and solutions to customers both at home at abroad.

Conclusion: why Malaysia customer choose us as his organic fertilizer production line machine supplier?

- One stop service: from solution to machine installation and after sale maintenance.

- Professional solutions service provided. Based on customers’ demands, recommend our best solutions to our customers.

- Quality and high performance organic fertilizer machines. All our fertilizer are manufactured in high quality, meeting industrial fields higher standard.

- Professional after sale service: onsite installation and stuff training services provided.

Organic Fertilizer Production Line Onsite Installation