The material coming out of the dryer has a high temperature and cannot be directly screened and packaged. It must be cooled. By using compost rotary cooler, organic composts temperature can be reduced. What’s more it can also further reduce the moisture content of the raw material, improving particle strength and appearance quality of the granular compost.

What materials or compost fertilizers can be cooled by the roller compost cooler?

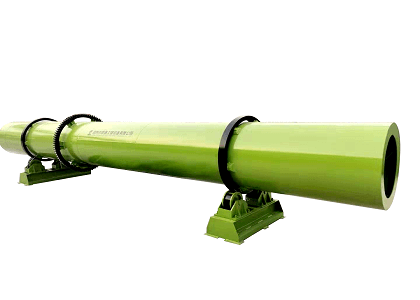

Similar to the rotary drum dryer, the cooler is also suitable for powder, granular, especially for the strong bonding materials. It also has a horizontal drum structure, and gear transmission system. The rotary drum cooler manufactured from ShunXin fertilizer machinery is perfectly designed for finished compost fertilizers cooling.

ShunXin manufactured rotary cooler working process

After the material is input into the cooling machine, in the rotating drum, the material is conveyed forward by the inclination angle of the cylinder body, and the cylinder body is arranged to be lifted. The material plate continuously moves and disperses the material, and a discharge dust removing device is prepared in the discharge chamber to rapidly cool the material entering the drum, and the cooled material can enter the next process. The front and rear races are supported on the retaining wheel device and the idler device, and the retaining wheel device prevents the cylinder from tilting back and forth. The transmission device is driven by a cyclical pinwheel reducer to rotate the large gear on the cylinder body, and a sealing device is arranged at both ends of the cylinder body to prevent air from entering the cylinder body. During this process, your granular compost fertilizer can be bagged or packaged.

A higher performance compost cooling equipment you can count on

Large capacity for your industrial scale compost production reference. The utmost productivity of the cooler reaches 10 ton per hour which can meet your mass production requirements.

The supporting power of the fertilizer cooler is within the ranges of 7.5 kW to 75kW. It can meet different counties electric working conditions.

Various material applicable. Powdery, granular, sticky materials are all applicable to this cooling equipment.

ShunXin dedicated fertilizer cooler machine can meet all your requirements whether in the machines configurations and specifications, the factory can tailor to you.

Compost rotary cooler maintenance suggestions

Right here below, the factory recommends you the following tips for the cooling machine maintenance and operation reference.

- When start using the rotary cooler, stop inspection and be sure there is no one under the machine for safety sake;

- Regularly add calcium-based grease to the bearing parts;

- Check the temperature of the bearing part, the maximum shall not exceed 60 °C;

- The cylinder should not have one-way turbulence and severe reciprocating movement;

- The rotating gear shall not have severe vibration and excessive noise;

- The motor runs smoothly and the current does not fluctuate significantly;

- The motor should have good grounding protection;

- Regularly open the cleaning door to clean the inside of the cylinder and the material entering and leaving the chamber;

- Before using the cooler, check the gearbox, whether there is oil in it. After the initial operation for 100h, replace the new oil. Then change the new oil every 1000h, the maximum time interval is one year.

ShunXin compost rotary cooler is a dedicated fertilizer cooler for finished fertilizer products, such as organic fertilizers, manure pellets cooling applications. More details on the machine’s costs, prices, and specifications, be free to contact us.