In this organic fertilizer production project solution case, the author will introduce the factory’s solution on Indonesian customer’s organic fertilizer business on Gourmet Powder Factory wastes treatment. We recommended a 3 ton per hour output organic fertilizer production line to our Indonesiian customer. And in his raw material processing, we also recommend and tailor our best available machines to his production line. The detailed information on the project solutions, machinery manufacturing, raw materials processing as follows just for customers reference.

Project overview on the organic fertilizer production business in Indonesia

What kind of solutions Indonesian customer want to quorate for our organic fertilizer factory?

This Indonesian customer opens a Gourmet Powder Factory, and every day there is tons of CMS wastes produced from the factory. Through the internet and his friends in the same industry, he gets to know us, can provide solutions and machines to recycle organic wastes into valuable fertilizers.

What type of organic fertilizer production line solutions do we recommend for our customer in Indonesian?

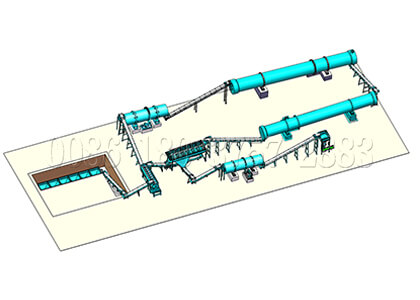

Since customer wants to find a new line for organic fertilizer production, and he wants to make granules fertilizer for commercial purpose, the engineer provides a complete fertilizer production line solution with the capacity of 3 tons per hour to make pellet fertilizer for him.

Organic fertilizer production requirements on the raw materials

Organic materials types whether available to make organic fertilizer

To start up an organic fertilizer production business, the key point is the raw materials, when organic materials cannot meet the standards of producing fertilizers, even if customer want to recycle their organic wastes and turn them into valuable fertilizers to make money, it is not cost-effective. Raw materials, like kitchen wastes, organic matters and capacities usually not enough, and MSW contains many parts like plastics etc. The main raw materials of our Indonesian customer are CMS and solid wastes, to a certain degree, it will be ok to make organic fertilizer.

Forms of organic materials to make fertilizer

The second requirement on the organic materials to produce organic fertilizer is the proportion of different types of organic materials taking. A proper proportion of different types of organic fertilizer production materials will ensure to make a high-quality fertilizer product as well. In this Indonesian customer’s organic raw materials, his main organic material is solid waste. In the solid wastes, there are palm kummel cake, carbon, humus, wood fiber, clay, calcium, etc. These organic materials are perfect materials to make organic materials. What’s more, they are dry organic materials, they are ideal to make powder and granule fertilizers.

Organic moisture contents in the organic materials

The moisture content of the raw materials is also quite important to make organic fertilizer, especially in pellet organic fertilizer production, if there is too much water content in the raw materials, it is very hard to make fertilizer granules whether customer choose any fertilizer granulators. The other type of organic material is rich moisture content organic materials which contains 70%. Our Indonesian has tried different types of granulators, it didn’t work well since too much moisture content. This author has already had three fertilizer production lines, and he was now to find an effective organic granulator to process the raw materials.

Our solutions to reducing the moisture content of customers CMS materials.

There are different ways to reduce the moisture content of the raw materials, one is to add dry materials to dilute the moisture of the raw materials. And the other way is to find a machine to remove the moisture content of the organic materials. In our factory, we have manufactured different types of dewatering and drying machines customer can choose from us to reduce their raw materials moisture content, fertilizer dewatering machine and rotary drum driers are both available for customers. In this customer case, we recommend our Indonesian customer add bentonite and straw materials to his materials to reduce the moisture content. For one thing, these materials can dilute the additional moisture content of the raw materials, then it will be east to make granules; for another, it also adds other organic matters to the organic materials, it will help customer produce quality fertilizer.

.jpg)

On the fertilizer machines manufacturing, what customers requirements on our machines?

Since Indonesian customer needs to make granules fertilizer and the fertilizer granulating machine he used now was broken, and he wanted to order a new one from us. He chooses a 3 meters pan granulator for his existing granular organic fertilizer production line.

In the organic fertilizer pan granulation configuration, the customer needs us to manufactured him a high-performance granulating machine to promote his organic fertilizer production efficiency. To meet customers such requirements, our factory manufactured him a disc fertilizer pellet machine with extra motor for automatic cleaner. Configured with such design, customer can make organic fertilizer granules faster. In the manufacturing materials of the pan granulator machine, we usually use 304 stailess carbon steel, and configured with anti-worn components, customer can use this granulator in a longer time.

What customized service did we provide to our Indonesian customer in his granular organic fertilizer production business to prolong the service life of the granulator machine?

As a professional organic fertilizer manufacturing company, we can tailor different types for organic fertilizer machines based on customers requirements. In this production line, customer needed a high-performance granulator with a longer service lifetime than his existing granulator, thus we configured him an extra motor and an automatic cleaning device to let customer can use this granulator make granules faster. With automatic cleaning configurations to the pan granulating machine, sticky raw materials can be cleaned automatically, reducing the erosion to the machine. In the raw materials to make pan granulator, we use 304 stailess steel, the high-quality steel to fertilizer machine, enabled a high temperature resistance and anti-erosion feature to the granulator. All these configurations prolong the service lifetime to the granulator.

Conclusion: 3 ton per hour organic fertilizer production line for sale in Indonesian successively

With professional services and solutions, we finally won our Indonesian customer’s recognition. We designed him a 3 ton per hour output granules fertilizer production line. Right now, the production line runs well on customers fertilizer business, and he has also received quality fertilizer products from the machines we produced to him. Customers need fertilizer production lines, e free to contact us.

1-2 ton organic fertilizer production line installation in India